Raysoar offers multiple CO2 laser lens types, including plano-convex, meniscus, and aspheric designs. These options allow B2B clients to tailor beam profiles for specific laser cutting or engraving tasks. Our in-house expertise supports reliable selection and bulk procurement.

Built for durability and performance, Raysoar laser optics withstand high-temperature and high-power environments. With advanced coatings and surface quality, our optics ensure reduced reflection and consistent beam shaping. Raysoar partners with B2B clients globally to deliver scalable solutions in industrial laser technology.

Our collimator lens for laser applications are built to reduce beam divergence and maintain parallelism, enabling reliable performance in demanding industrial settings. Raysoar supports B2B customers with consistent quality and professional support throughout their procurement process.

Raysoar delivers laser optics that improve beam control and focus accuracy in industrial applications. Our optics maintain optical clarity and power efficiency under demanding conditions. Businesses rely on Raysoar’s quality craftsmanship and in-house engineering to optimize system performance and reduce downtime in production lines.

Raysoar specializes in laser optics that meet the performance standards of today’s manufacturing and processing systems. With precise coatings and durable materials, our products serve B2B buyers who demand consistency, efficiency, and compatibility with advanced laser machines.

Shanghai Raysoar Electromechanical Equipment Co.,Ltd. is a professional company that provides one-stop products and services for the maintenance, repair and operation (MRO) of modern laser industrial equipment. Raysoar provides various consumables and related key parts of laser machine. Our service covers on-site maintenance for laser industrial equipment, transformation and upgrade of key part and equipment, training and promotion of new technology for laser industrial application.

Raysoar always offers entire, economic and efficient products and service for industrial laser machine users and developing self-owned products line depended on over 20 years experience in industrial laser application field.

Always provide comprehensive range of products cover consumables, accessories, function parts and machines as well.

Make the cost-effective selection for every product.

Always keep efficiency in production and service.

Be professional with over 20 years experience in the service for every customer.

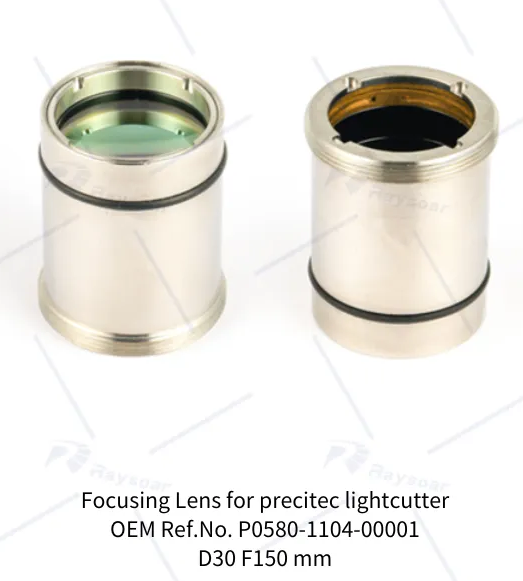

Raysoar provides lenses, mirrors, beam splitters, and protective windows designed for industrial laser applications with high-power compatibility.

Yes, Raysoar offers customized laser optics based on client requirements, including size, coating, material, and optical specifications.

Raysoar optics are compatible with a wide range of CO₂, fiber, and solid-state laser systems commonly used in industrial manufacturing.

Raysoar uses advanced inspection and testing equipment to verify optical performance, including transmission rate, surface accuracy, and coating quality.

Applications include cutting, welding, engraving, drilling, and marking across various industrial sectors requiring high precision and efficiency.