Raysoar’s CO2 laser cutting nozzle is engineered to enhance laser focus and gas flow control, resulting in cleaner cuts and reduced thermal deformation. Built for long-term use in industrial settings, our nozzles are ideal for clients looking to maintain high-quality output across production batches.

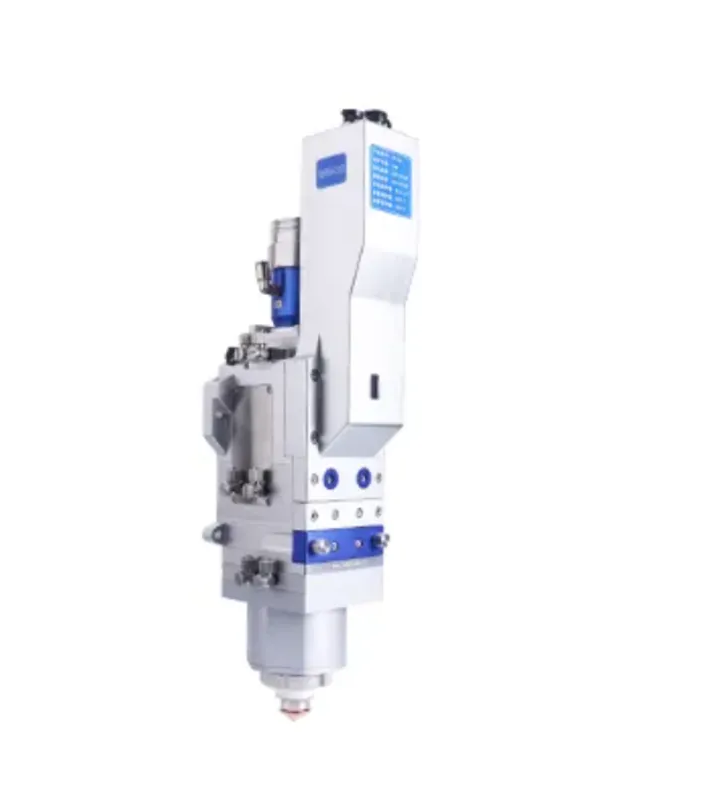

Built for modern fabrication lines, Raysoar’s fiber laser cutting head offers unmatched cutting precision and speed. With robust sealing and advanced cooling features, it ensures stable output even during continuous operations. Raysoar supports B2B partners with flexible configurations and ongoing technical support.

Raysoar manufactures precision CO2 laser cutting nozzles that deliver consistent airflow and reduce thermal impact on workpieces. Ideal for wood, acrylic, and other materials, our nozzles are engineered for efficiency and long service life. Raysoar serves B2B clients seeking dependable, high-volume laser processing components.

Raysoar offers laser cutting solutions that optimize manufacturing efficiency. Our equipment is designed for high-speed operation and seamless integration into existing production lines, minimizing downtime and maximizing output. Trust Raysoar to enhance your manufacturing processes with reliable and efficient cutting technology.

Raysoar’s commitment to quality makes us a top choice for the best fiber laser cutting head in industrial-grade applications. Our advanced optics, modular design, and heat-resistant materials meet the requirements of automated production lines. Businesses trust Raysoar for reliable products and tailored support across industries.

Shanghai Raysoar Electromechanical Equipment Co.,Ltd. is a professional company that provides one-stop products and services for the maintenance, repair and operation (MRO) of modern laser industrial equipment. Raysoar provides various consumables and related key parts of laser machine. Our service covers on-site maintenance for laser industrial equipment, transformation and upgrade of key part and equipment, training and promotion of new technology for laser industrial application.

Raysoar always offers entire, economic and efficient products and service for industrial laser machine users and developing self-owned products line depended on over 20 years experience in industrial laser application field.

Always provide comprehensive range of products cover consumables, accessories, function parts and machines as well.

Make the cost-effective selection for every product.

Always keep efficiency in production and service.

Be professional with over 20 years experience in the service for every customer.

Raysoar's laser cutting equipment can process a variety of materials, including metals like steel and aluminum, as well as non-metal materials, depending on the machine specifications.

Yes, our equipment is designed for seamless integration into existing production lines, with customizable interfaces and control systems to match your operational requirements.

Regular maintenance includes cleaning optical components, checking alignment, and ensuring proper cooling. Raysoar provides detailed maintenance guidelines and support services.

Yes, Raysoar offers comprehensive training programs for operators, covering machine operation, safety protocols, and maintenance procedures to ensure optimal performance.

Raysoar provides ongoing technical support, spare parts availability, and maintenance services to ensure the longevity and efficiency of our laser cutting equipment.