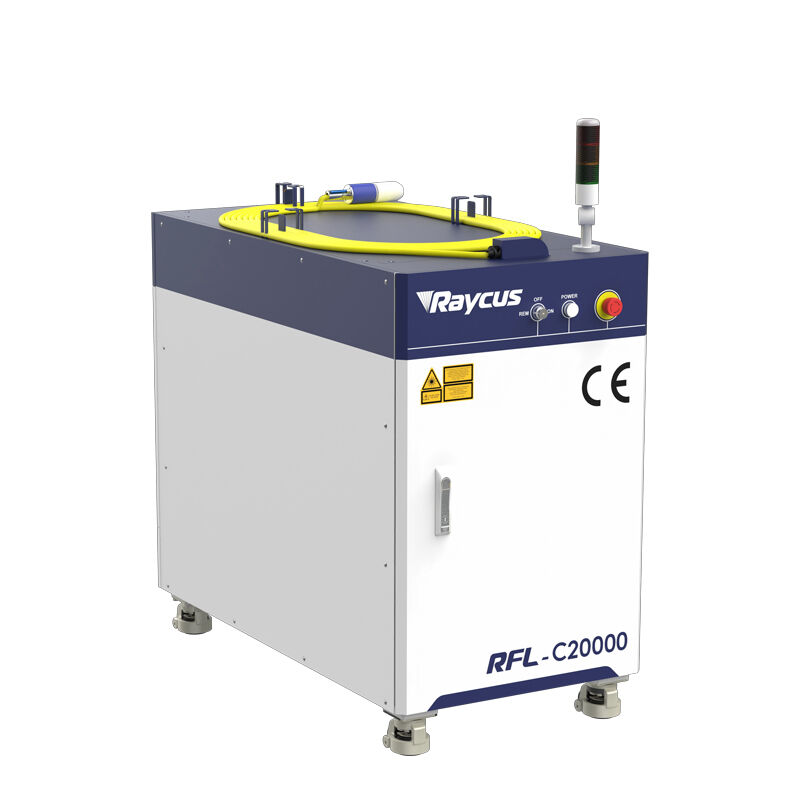

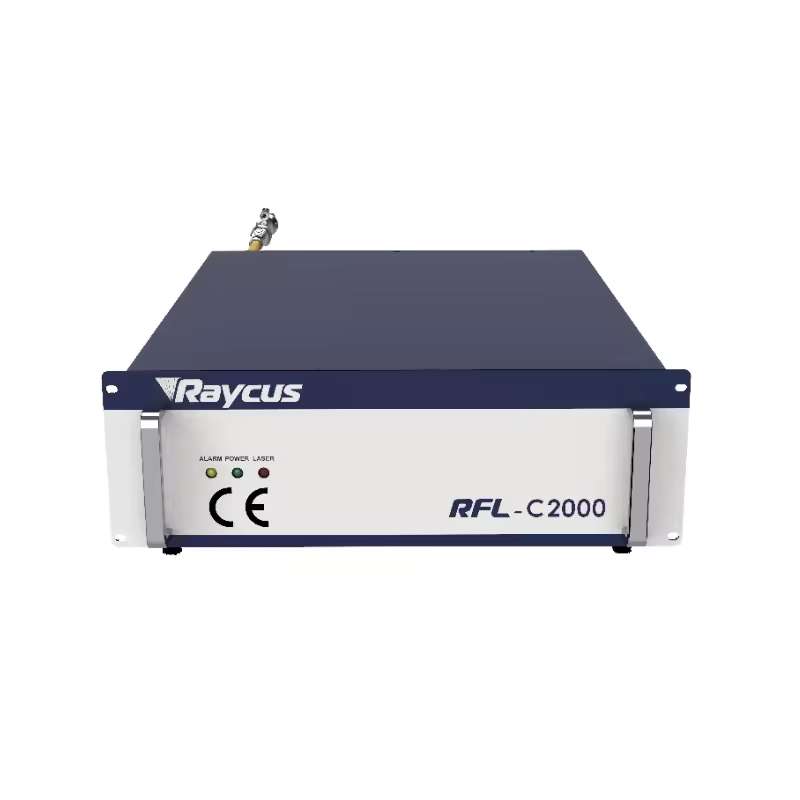

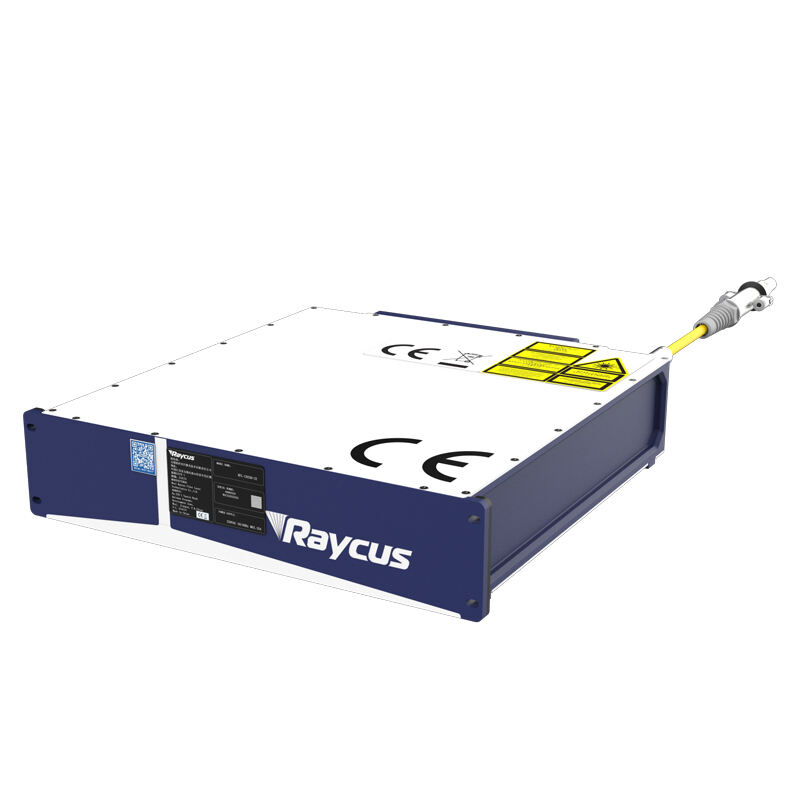

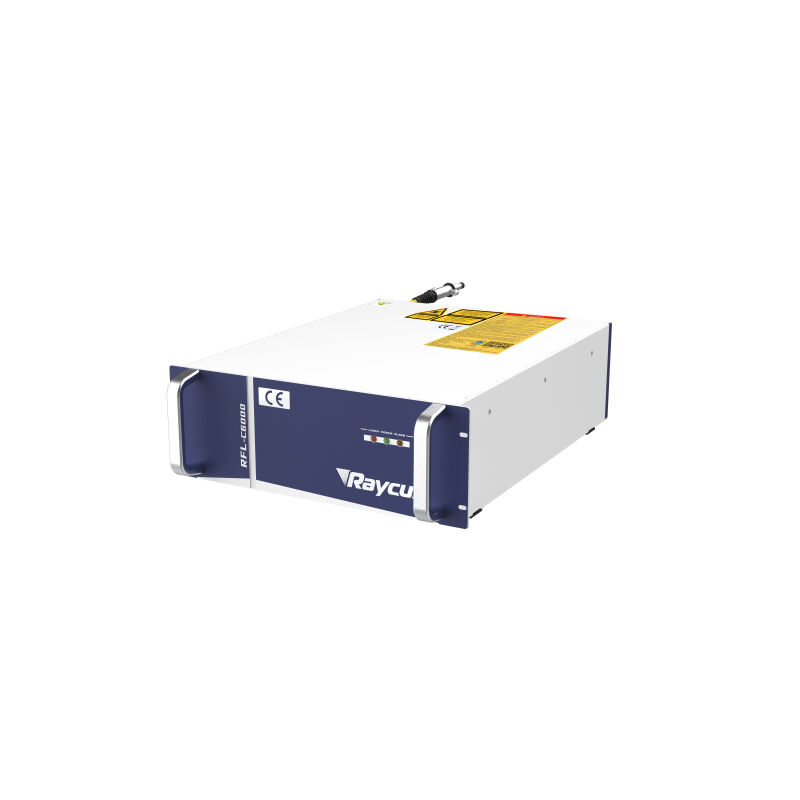

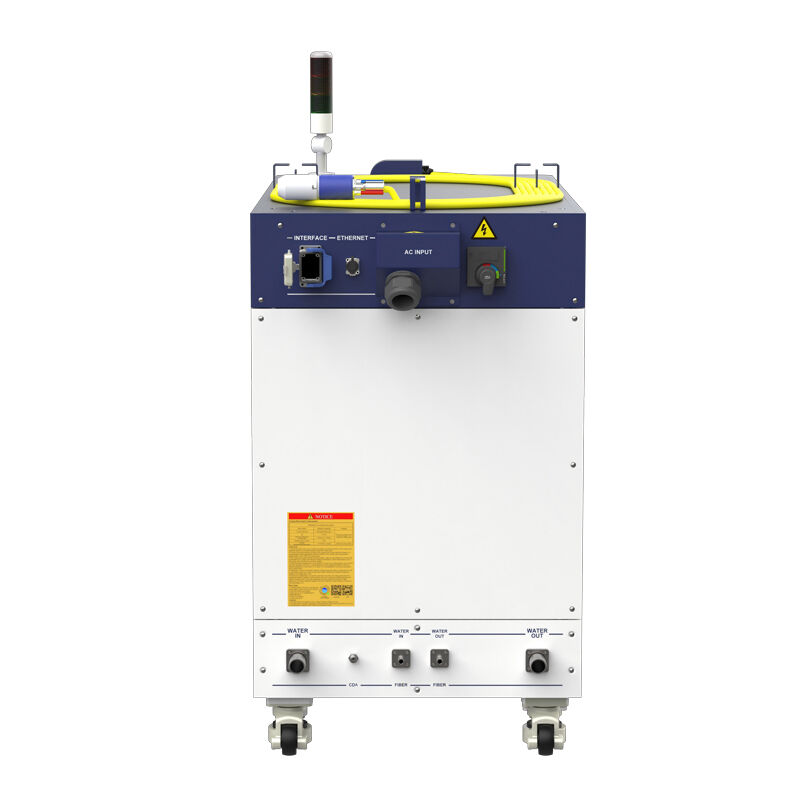

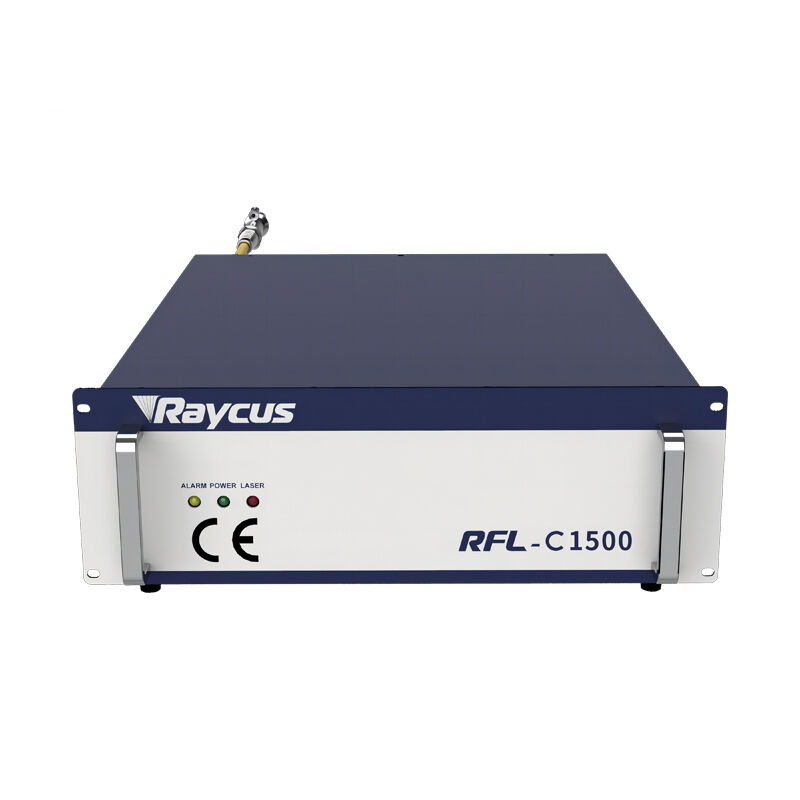

Unmatched Performance with Raycus Fiber Laser Source

The Raycus Fiber Laser Source stands out in the laser industry due to its exceptional performance, reliability, and efficiency. With over 20 years of experience in the laser application field, Shanghai Raysoar Electromechanical Equipment Co., Ltd. has developed a product that meets the diverse needs of industrial users. The Raycus Fiber Laser Source offers high beam quality, excellent cutting speed, and low operational costs, making it an ideal choice for various applications including metal cutting, engraving, and welding. Our commitment to providing comprehensive, economical, and efficient solutions ensures that your laser equipment operates at its best, enhancing productivity and reducing downtime.

Get A Quote