Optical laser sources stand as a foundational pillar of modern advanced manufacturing, powering applications that demand an unparalleled combination of high power and micron-level precision, such as industrial cutting, deep engraving, and hermetic welding. At Shanghai Raysoar Electromechanical Equipment Co., Ltd., we fundamentally understand that our clients' productivity, quality, and competitive edge are intrinsically linked to the performance and reliability of their core laser technology. This is why we dedicate ourselves to engineering and supplying superior optical laser sources that meet the exacting standards of the world's most demanding sectors, including automotive, aerospace, medical device manufacturing, and semiconductor fabrication.

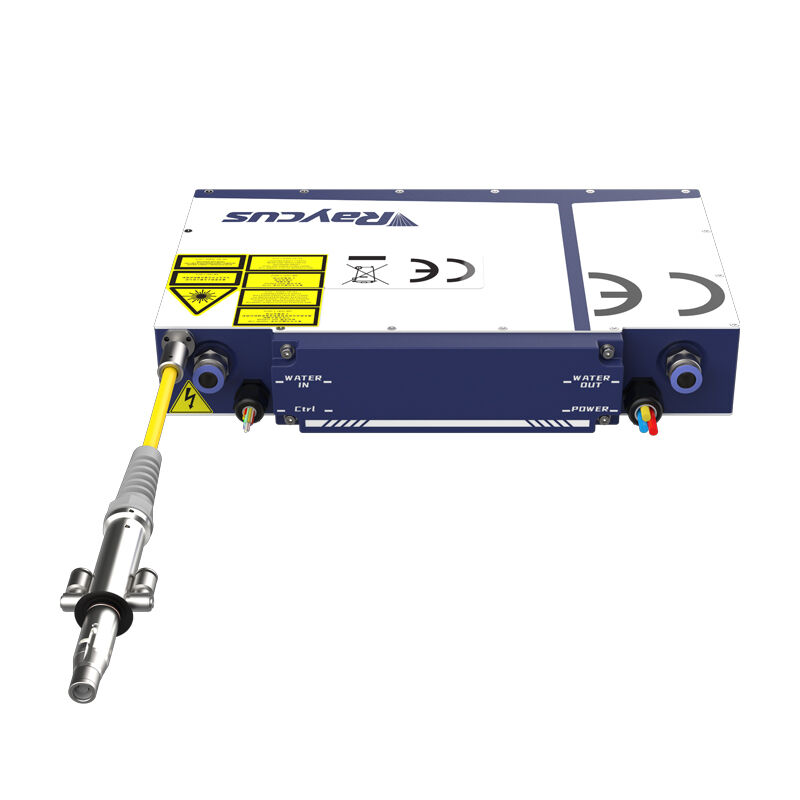

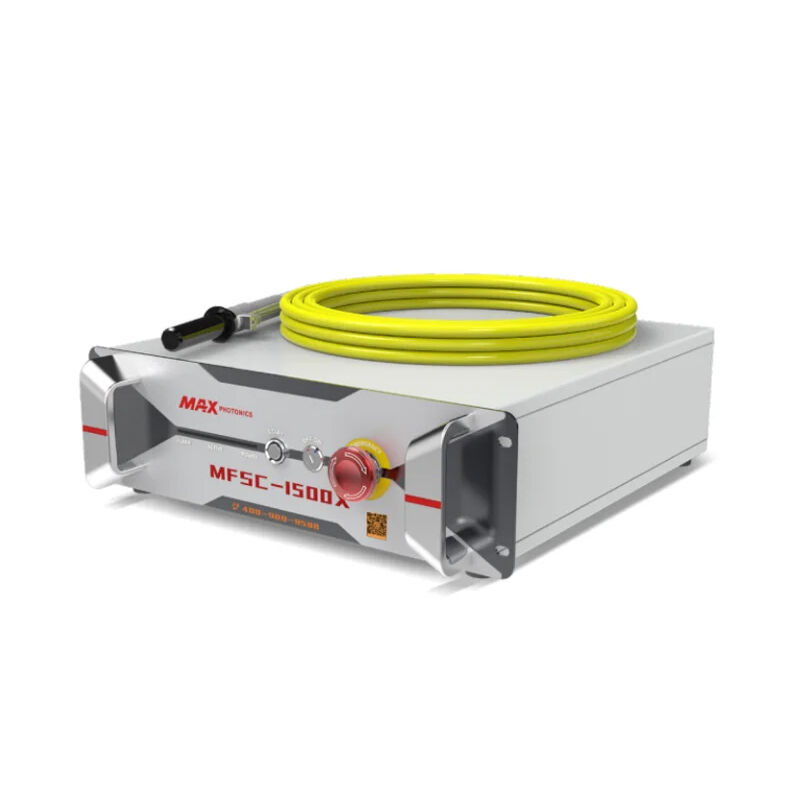

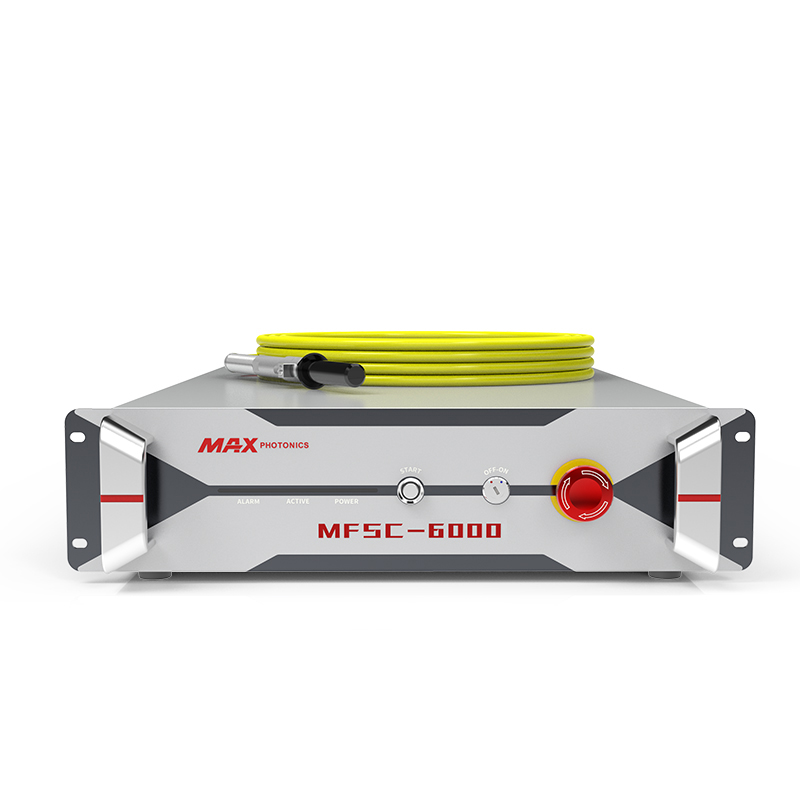

Our journey, spanning over two decades of focused innovation and application expertise, has been built on a commitment to pushing the boundaries of laser performance. We pride ourselves on developing reliable, technologically advanced, industry-grade optical laser sources that are designed for rigorous 24/7 operation. Our product portfolio encompasses a range of solutions, from high-power continuous wave (CW) lasers for heavy-duty cutting and welding to versatile pulsed lasers for fine marking and delicate material processing. Each system integrates the latest advancements in beam quality, stability, and energy efficiency, ensuring that our clients are equipped with tools that drive progress.

However, providing advanced hardware is only one part of our mission. We are equally committed to delivering comprehensive, latest-generation laser solutions. This means our engagement goes beyond the sale. Our customer-driven approach begins with a deep consultation to understand your unique material challenges, production throughput goals, and precision requirements. Our team of applications engineers works collaboratively with your experts to analyze workflows and recommend a tailored solution—whether it's a standalone laser source, a fully integrated processing head, or a customized parameter set for a specific material like high-strength steel, carbon fiber composites, or sensitive medical-grade polymers.

The tangible result of this partnership is a direct improvement in operational efficiency and a measurable decrease in total cost of ownership. Our lasers contribute to faster cycle times, reduced scrap rates from superior cut quality, and lower energy consumption. In highly regulated fields like medical device manufacturing, our sources enable pristine, permanent marking for traceability that complies with strict UDI regulations, while in aerospace, they facilitate the machining of complex, lightweight components with absolute dimensional integrity.

By optimizing these critical processes, we directly optimize our customers' productivity and enhance their value proposition in today's fiercely competitive global marketplace. Choosing Raysoar means more than purchasing a laser; it means entering a strategic partnership dedicated to empowering your manufacturing capabilities with robust, innovative, and precisely tailored optical laser technology, backed by deep industry knowledge and unwavering support. We provide the reliable technological foundation upon which industry leaders build their future.