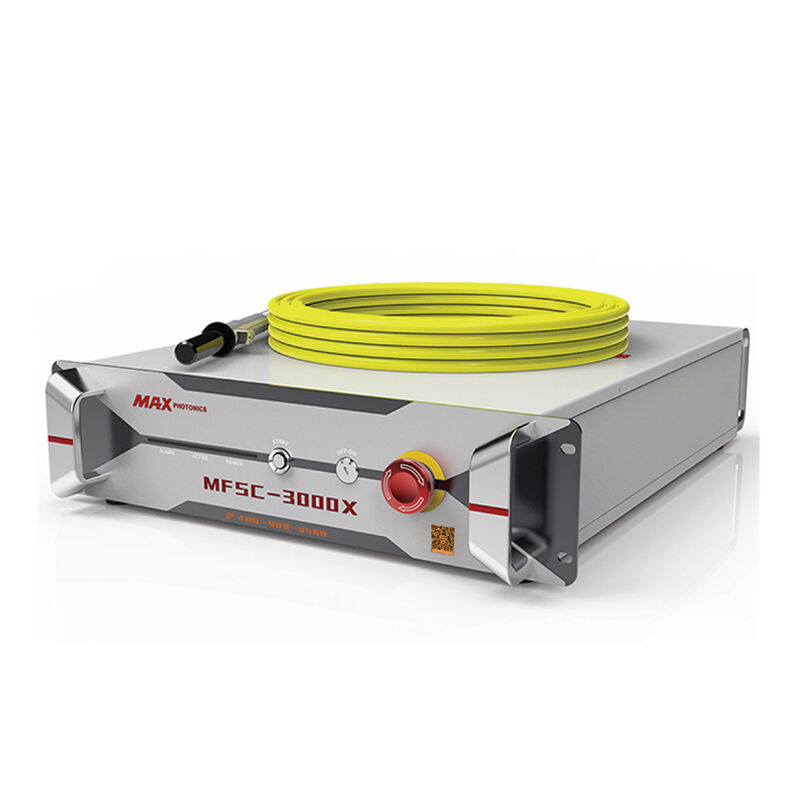

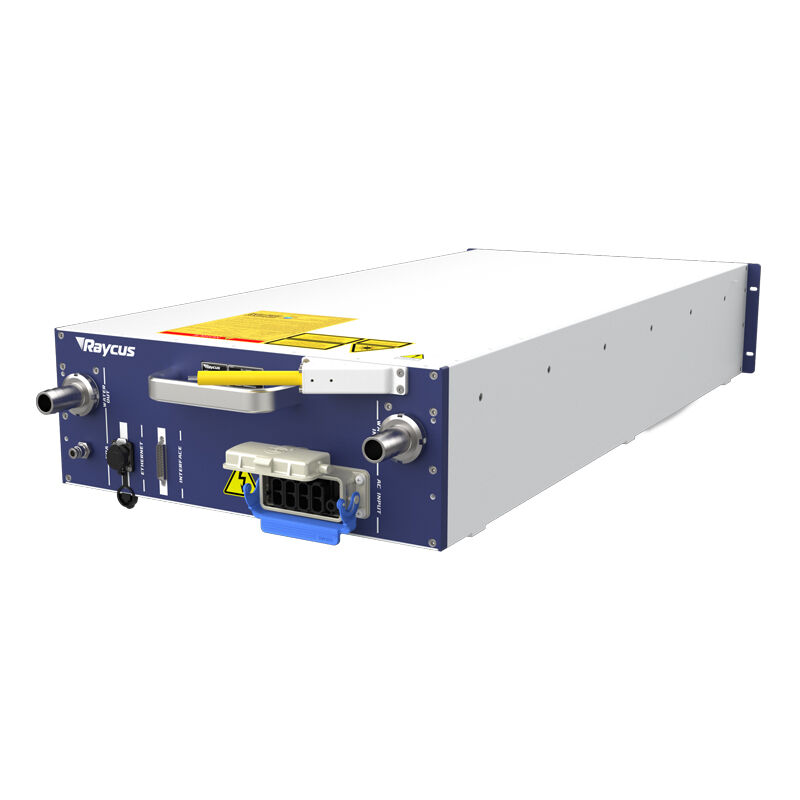

Shanghai Raysoar Electromechanical Equipment Co., Ltd, offers advanced laser sources for optical fiber applications. We design our laser sources to provide exceptional performance for varied industrial applications to optimize user productivity. Quality control on every laser source guarantees their efficiency and reliability. Understanding that every industry has different needs, we provide customized aligned to clients’ operational objectives. Our laser sources go beyond the expected performance for industrial laser sources. This is the reason we have the pride of countless businesses.