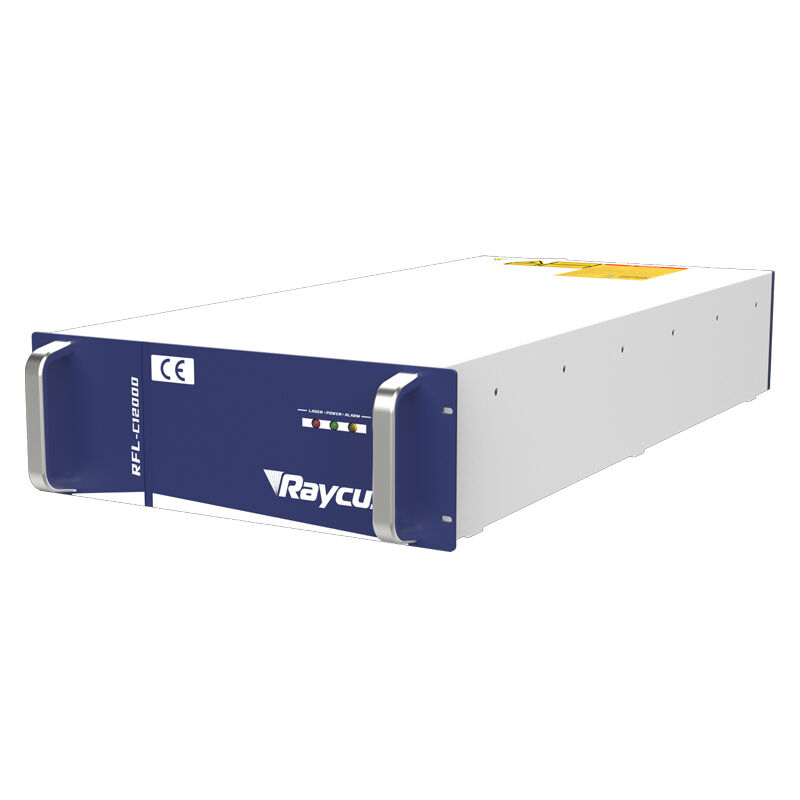

Unmatched Performance of 1000W Fiber Laser Source

The 1000W Fiber Laser Source from Shanghai Raysoar Electromechanical Equipment Co., Ltd. sets the standard for efficiency and precision in laser industrial applications. With over 20 years of expertise, our fiber laser source ensures high-quality cutting, welding, and marking capabilities. It offers superior beam quality, enabling intricate designs and reducing material waste. The compact design and low maintenance requirements of our laser source make it an economical choice for manufacturers looking to enhance productivity while minimizing operational costs. Furthermore, our comprehensive support services, including on-site maintenance and training, ensure that you maximize the potential of your laser systems.

Get A Quote