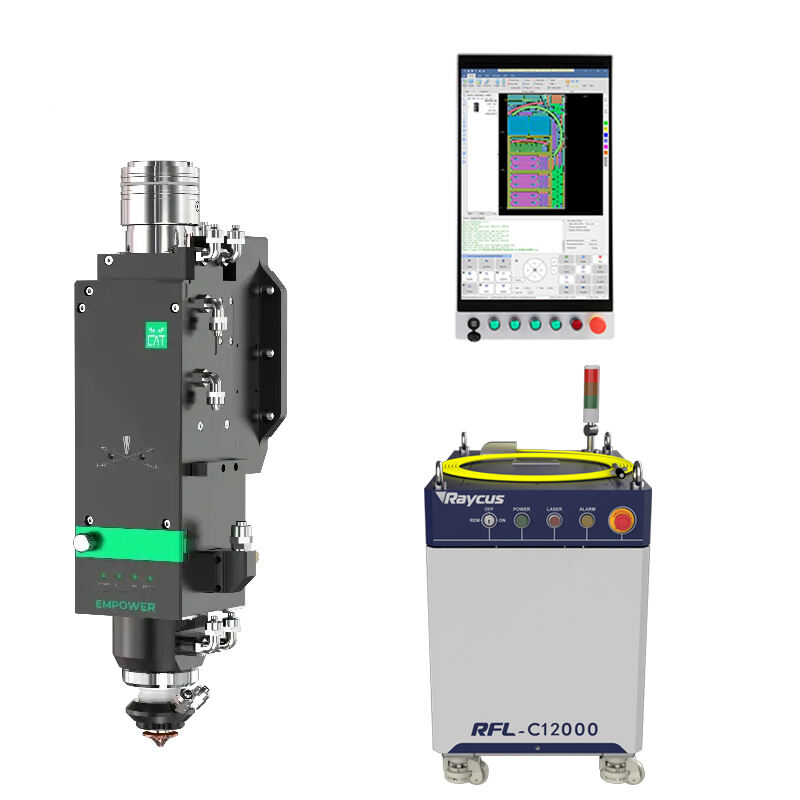

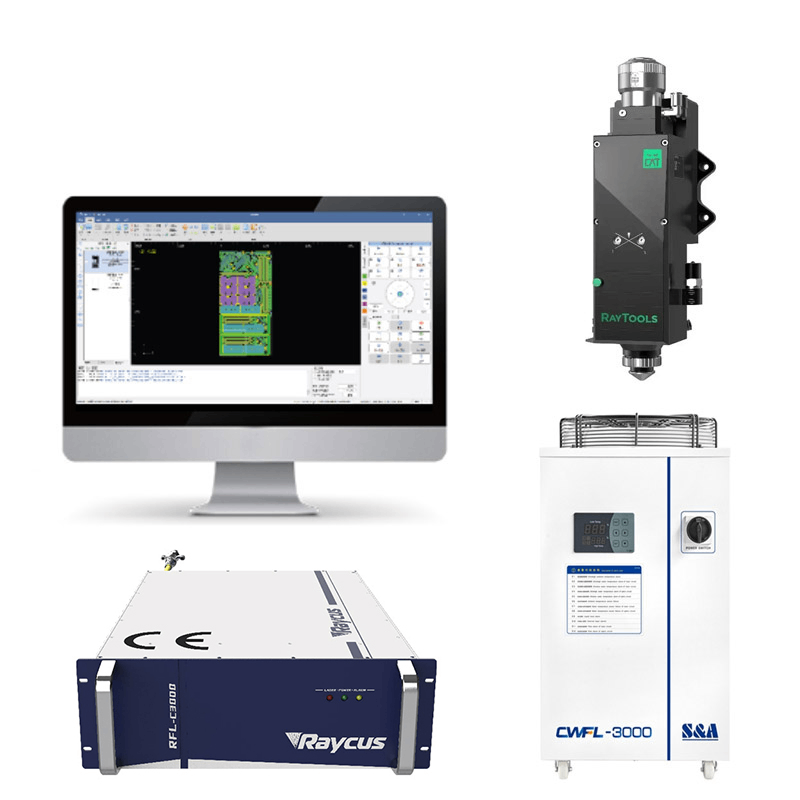

Fiber Laser Controller: The Brain Behind Automated Laser Operations

Learn about fiber laser controllers, the core components and architecture, and their role in driving automation and efficiency in laser welding machines. Discover the benefits of real-time processing, precision control, seamless integration, and the economic advantages of modern fiber laser controllers.

View More