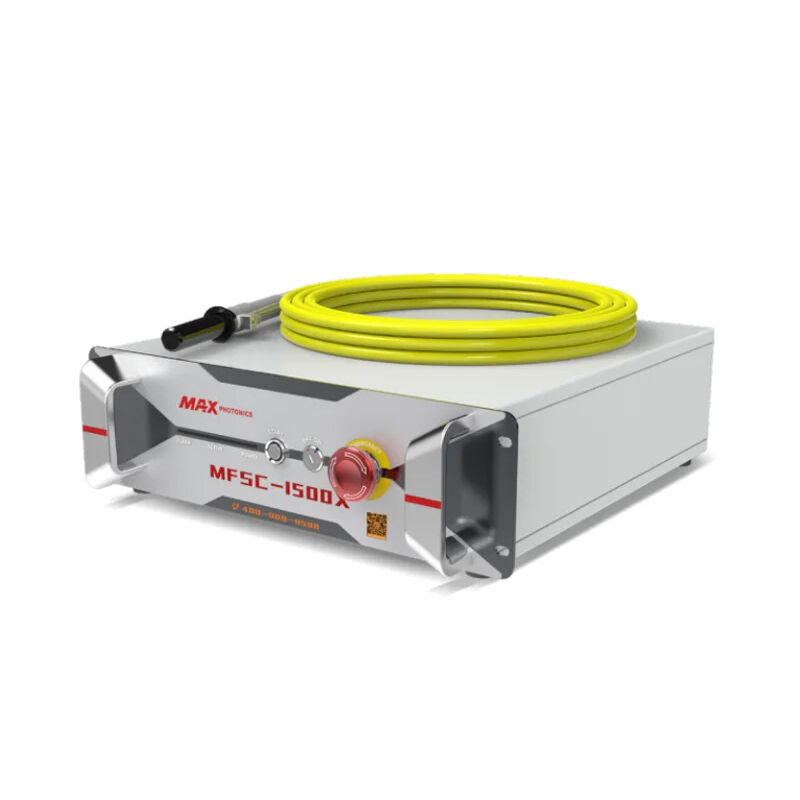

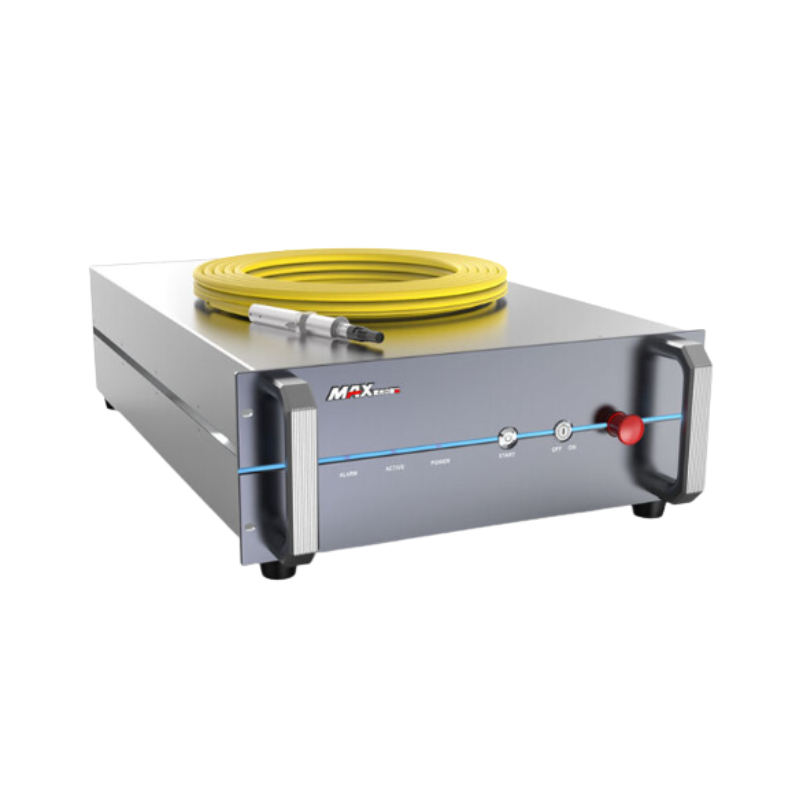

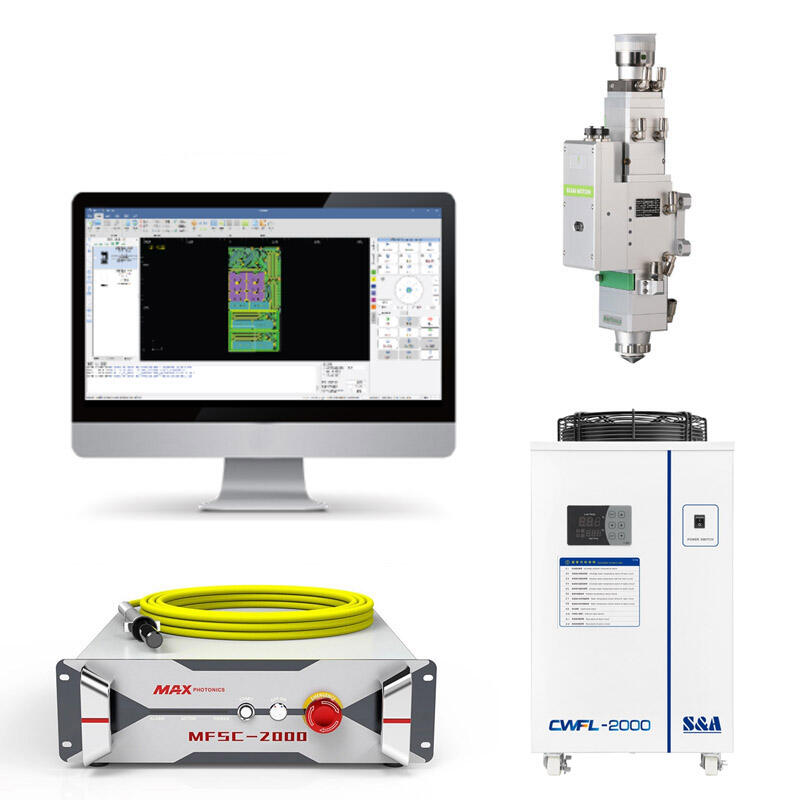

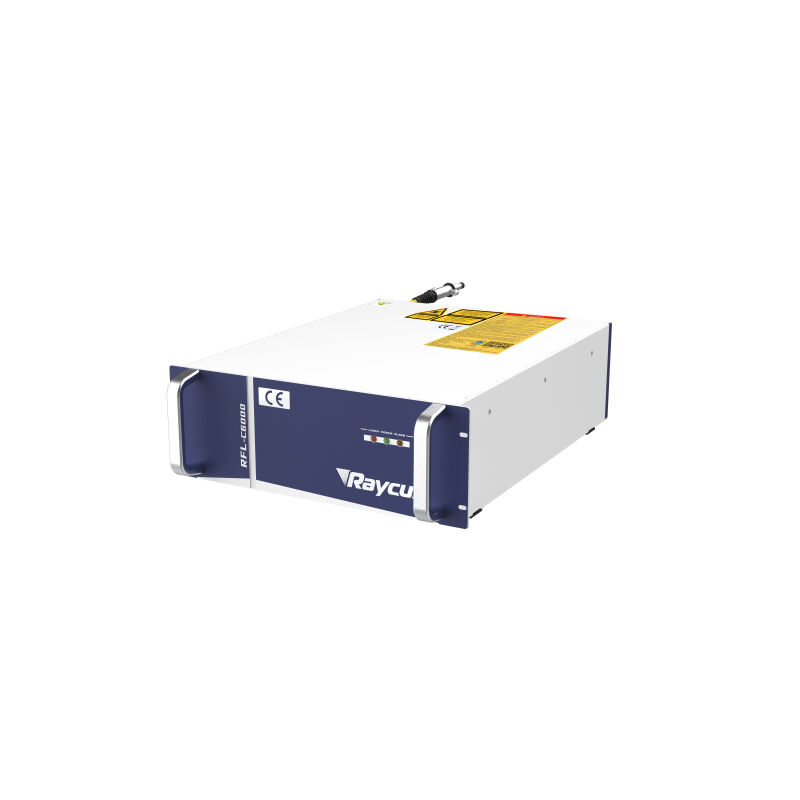

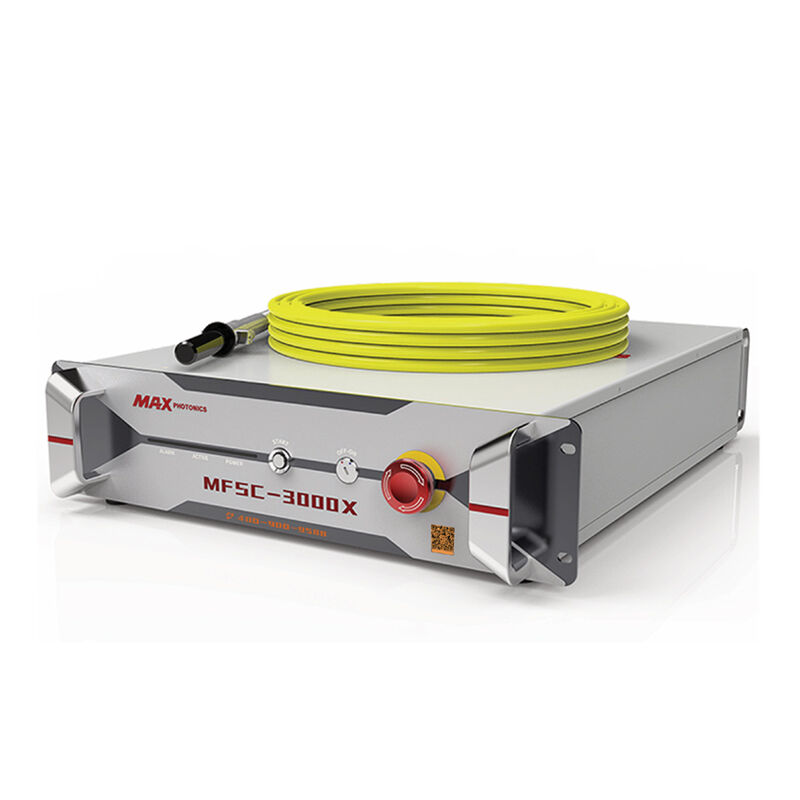

Maximize Your Laser Efficiency with Raysoar’s Fiber Laser Source

Raysoar’s Fiber Laser Source stands out in the industrial laser market due to its exceptional performance, reliability, and cost-effectiveness. Our fiber laser sources are engineered to deliver high precision and speed, making them ideal for a variety of applications, including cutting, welding, and marking. With over 20 years of experience in the laser industry, we ensure that our products are not only efficient but also tailored to meet the specific needs of our clients. Our commitment to innovation means that we continuously upgrade our technology to provide the best solutions for modern industrial applications.

Get A Quote