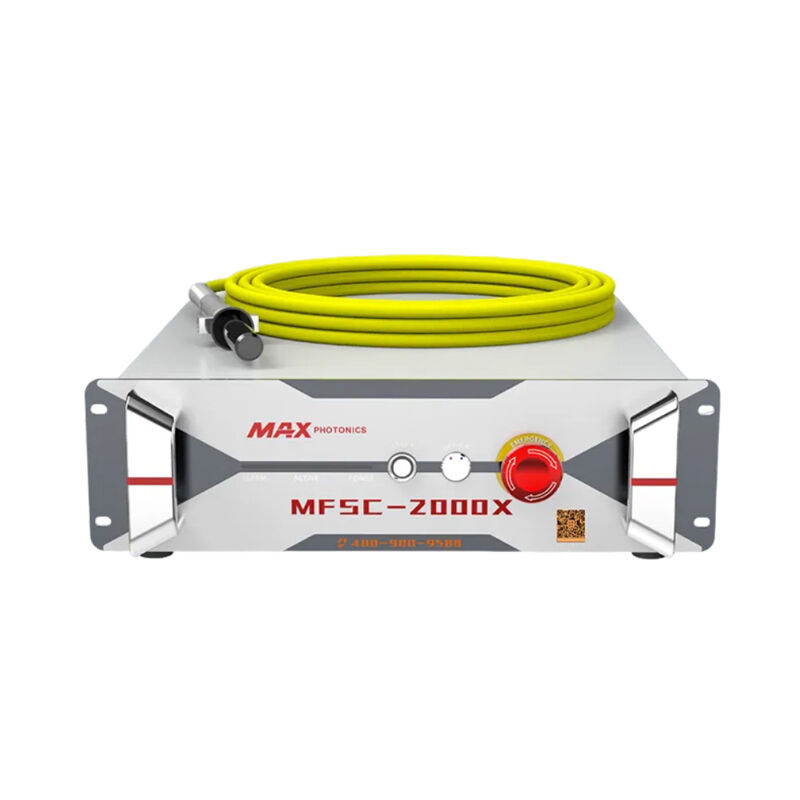

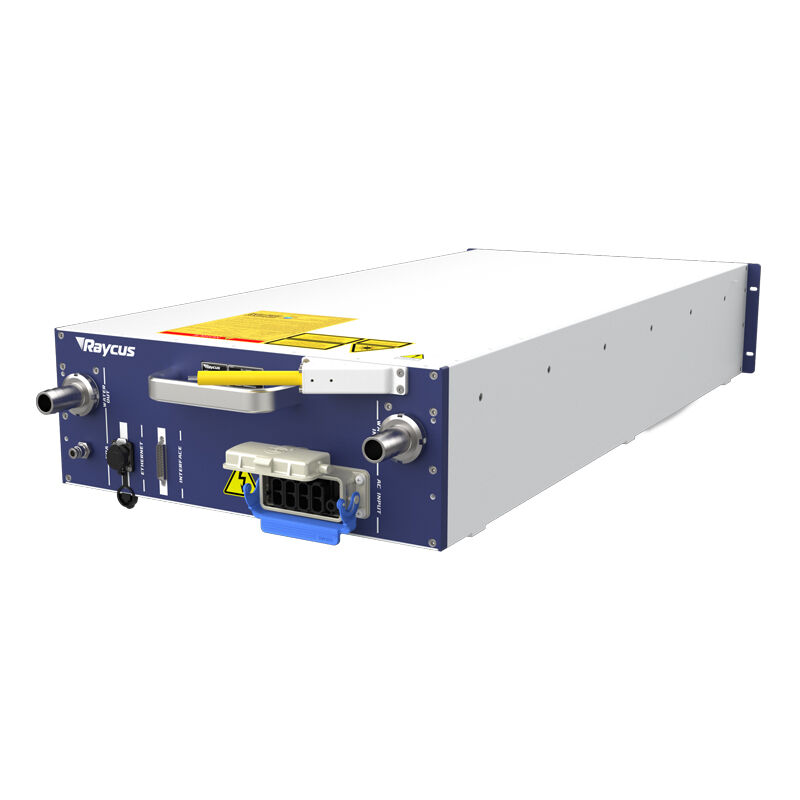

Max Fiber Laser Sources represent a significant leap forward in laser technology, masterfully combining raw high performance with engineered simplicity for unparalleled operational ease. This state-of-the-art laser source is not only powerful but is distinguished by its extended and superior beam quality (characterized by a low M² value), which is fundamental for excelling in high-level, precision-driven industrial construction and manufacturing. Its versatility is exceptional; cutting, welding, marking, and engraving are just the beginning of its capabilities. It seamlessly handles everything from fine micro-welding in medical device assembly to heavy-duty cutting of thick-section steel in structural fabrication, making it a truly adaptable core tool for modern industry.

The construction of every Max Fiber Laser Source is held to an uncompromisingly high standard. It features a detailed, robust design built around a monolithic, temperature-stabilized optical engine. This meticulous engineering ensures exceptional long-term stability and reliability. Each unit undergoes a rigorous battery of tests in simulated real-world conditions, verifying parameters such as power stability over time, beam profile consistency, and thermal management efficacy. Prior to shipment, every laser source is guaranteed to pass a final, stringent quality inspection and is verified to meet or exceed stringent international standards for performance, safety, and energy efficiency, including CE and relevant ISO certifications.

At Raysoar, we believe that customer service must evolve in tandem with technology. Our support structure is built around this principle, providing comprehensive, expert assistance from the initial planning and installation of the Max Fiber Laser Source through every subsequent phase of its operational life. Our team of application engineers works closely with clients to ensure optimal integration, while our service technicians provide proactive and responsive maintenance. This end-to-end partnership is designed with one clear goal: to drastically decrease operational downtime and boost your overall productivity. We understand the critical importance that dependable, high-performance equipment brings to your operations, and we are committed to being the partner that ensures you can rely on it completely, day in and day out. Our 20 years of laser application expertise is not just a history; it's the foundation of the proactive support and continuous innovation we provide today.