Shanghai Raysoar Electromechanical Equipment Co., Ltd. recognizes that the future of industrial maintenance, repair, and operations (MRO) lies in portable, powerful, and precise technology. In direct response to our customers' expressed needs for unmatched precision and operational efficiency, we have pioneered the development of our advanced Handheld Laser Source. This innovative tool is engineered not as a generic device, but as a targeted solution for the specific, tight requirements of diverse sectors—from automotive and aerospace manufacturing to electronics, shipbuilding, and energy infrastructure. We understand that downtime is the enemy of productivity, and our handheld laser source is designed to be the first line of defense, bringing advanced laser capabilities directly to the point of need.

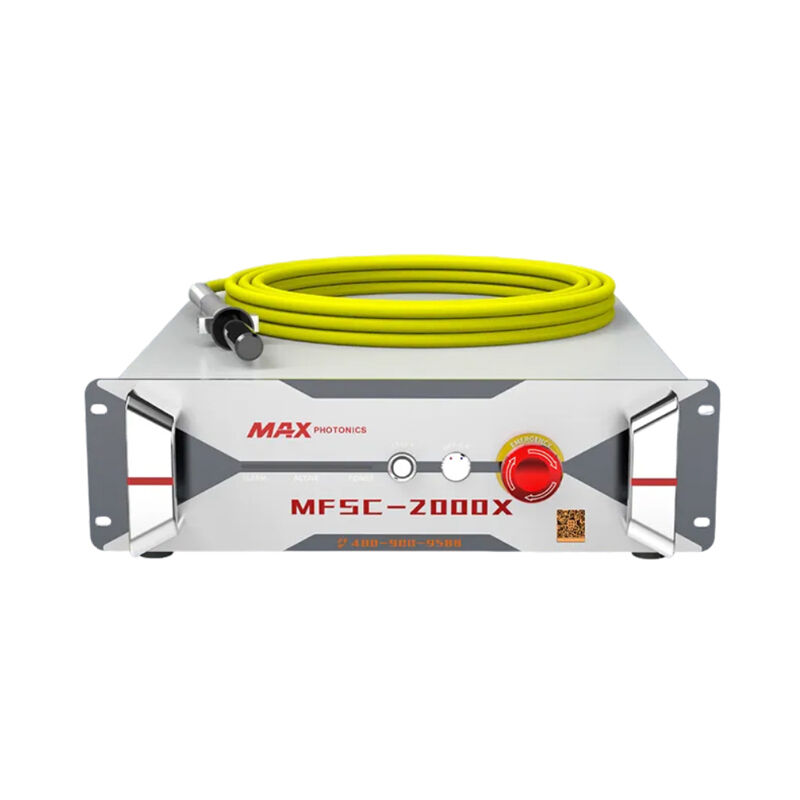

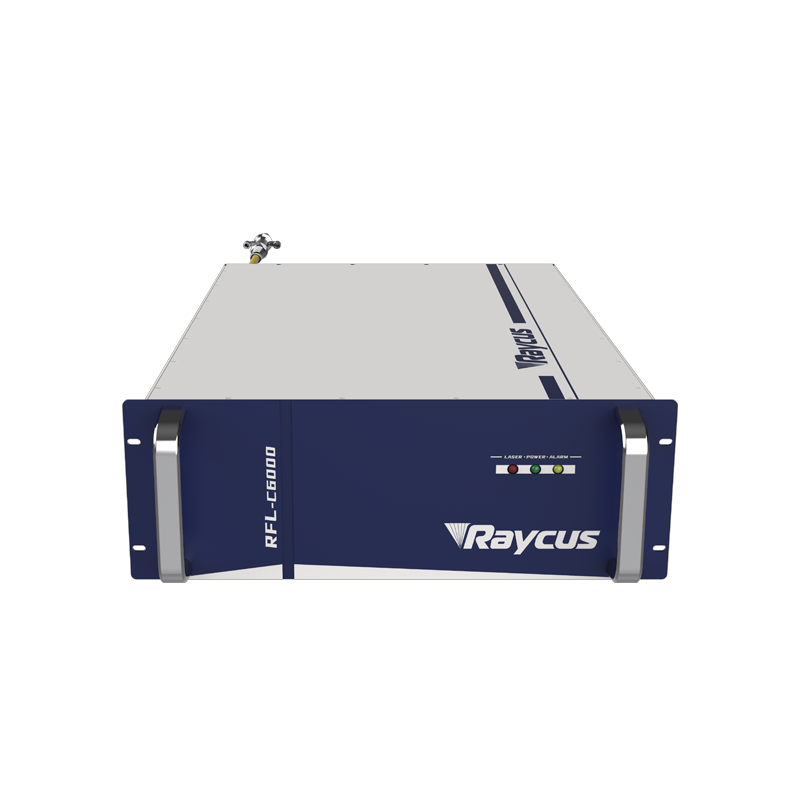

The production of our Handheld Laser Source integrates the very latest in laser innovation. At its core is a state-of-the-art fiber laser module, celebrated for its reliability, superior beam quality, and energy efficiency. Each unit is constructed from high-quality, durable materials selected to withstand the rigors of industrial environments, including shock-resistant housings and thermally stable components. This robust build quality ensures the device meets the high expectations for longevity and performance that professional industries demand.

We have meticulously designed every aspect for maximum utility and user adoption. Key features include adjustable laser power output, allowing an operator to tailor the energy delivery for tasks ranging from delicate cleaning of sensitive components to more robust material processing. The ergonomic design prioritizes operator comfort and control during extended use, reducing fatigue and enhancing accuracy. Furthermore, we have developed intuitive, user-friendly interfaces—from physical controls to digital displays—that make advanced laser technology accessible without a steep learning curve. This combination of features provides exceptional flexibility and adaptability, enabling a single tool to perform across a wide spectrum of applications within a facility.

As a developer and advanced provider, we believe superior technology must be paired with superior support. Customer service is a fundamental pillar of our business, not an afterthought. The value of our Handheld Laser Source is fully realized through comprehensive training and technical support. We offer tailored programs that equip maintenance teams with the knowledge and confidence to utilize the device effectively and safely, maximizing its potential. Our support network provides ongoing assistance, ensuring any operational questions are resolved promptly to maintain workflow continuity.

Raysoar’s commitment to continuous innovation and adaptation represents a significant advancement for the laser equipment industry. Our development roadmap is customer-driven, with each iteration aimed squarely at enhancing cost efficiency and operational efficacy for our users. By consolidating multiple repair and maintenance capabilities into one portable, high-precision tool, we empower businesses to reduce equipment downtime, minimize the need for external service contractors, and accelerate critical processes. In essence, our Handheld Laser Source is more than a product; it is a transformative operational strategy, encapsulating our dedication to pushing the boundaries of what is possible in industrial MRO through intelligent, customer-focused laser technology.