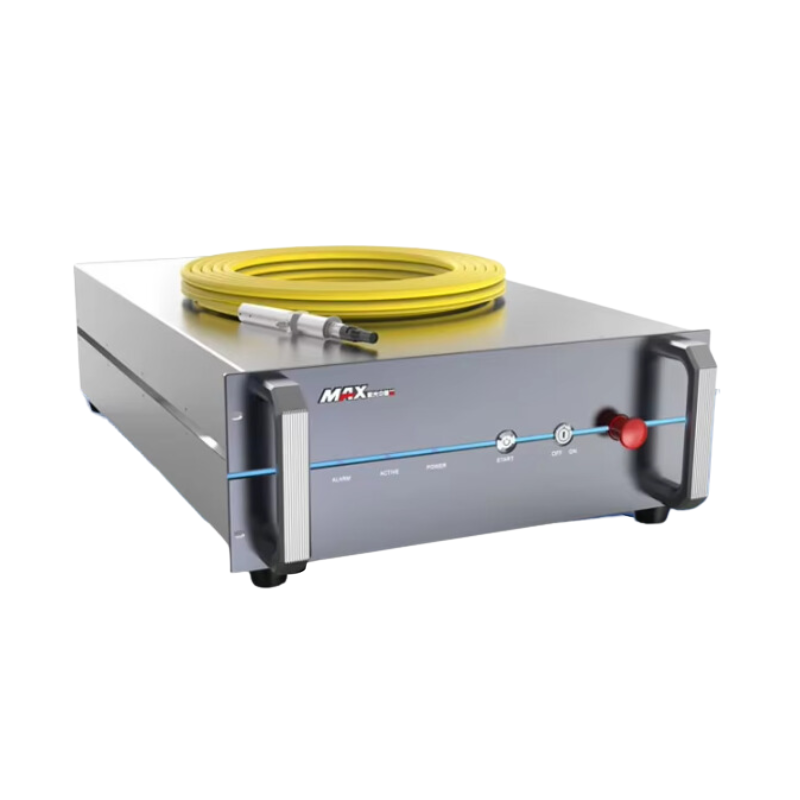

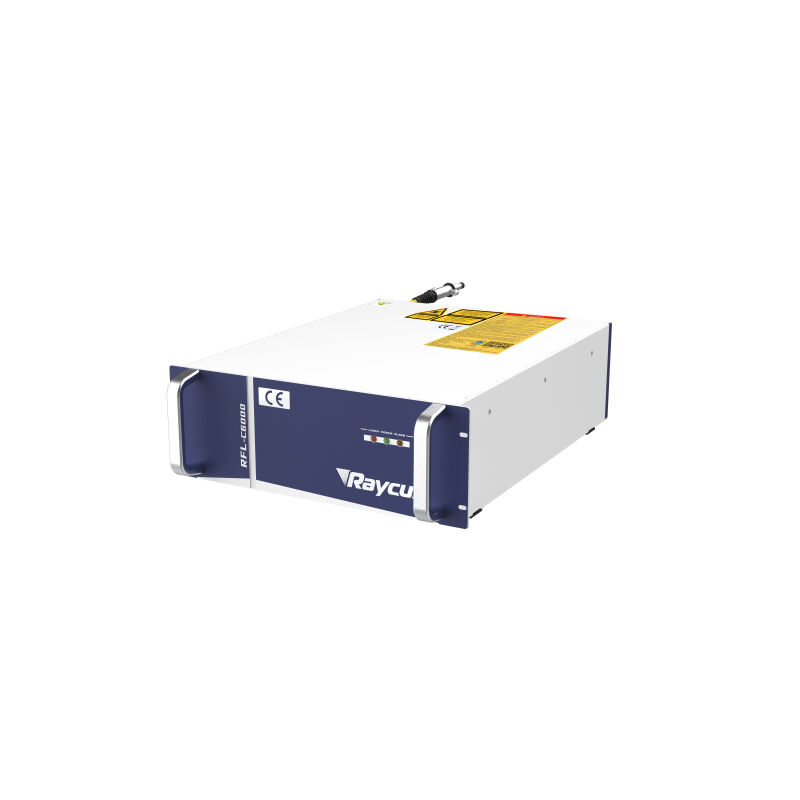

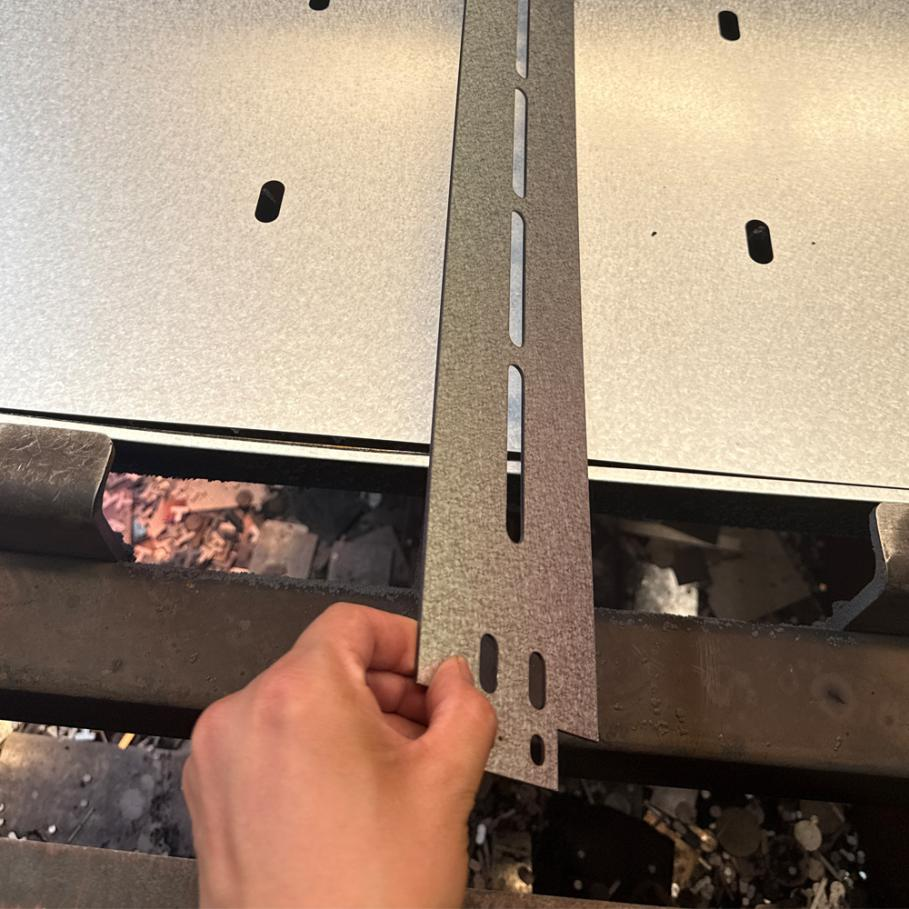

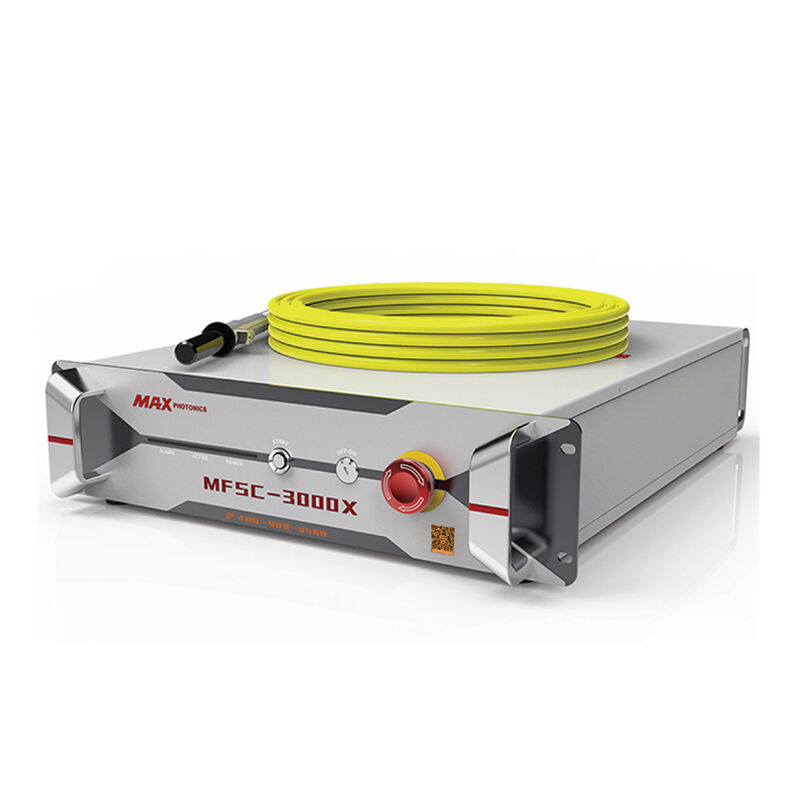

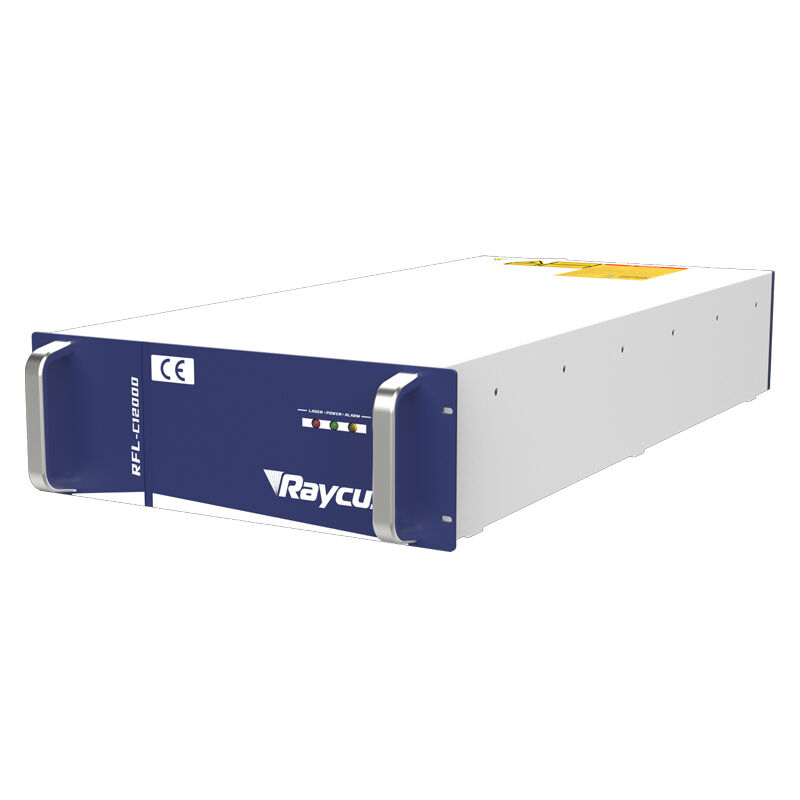

Unmatched Performance and Reliability of Fiber Optic Laser Light Sources

Fiber optic laser light sources represent the pinnacle of modern laser technology, offering unparalleled performance for various industrial applications. At Shanghai Raysoar Electromechanical Equipment Co., Ltd., we specialize in providing high-quality fiber optic laser light sources that enhance operational efficiency and reduce downtime. Our products are designed to deliver consistent power output, exceptional beam quality, and extended service life, making them ideal for demanding environments. With over 20 years of experience in the industrial laser application field, Raysoar guarantees that our fiber optic laser light sources meet the highest standards of reliability and efficiency, ensuring that your operations remain at the forefront of innovation.

Get A Quote