Customer Name: AB Hyllteknik Location: Sweden Industry: Furniture Manufacturing Manufacture Equipment: Bystronic Laser Cutting Machine 3KW 1 unit &...

Share

Customer Name: AB Hyllteknik

Location: Sweden

Industry: Furniture Manufacturing

Manufacture Equipment: Bystronic Laser Cutting Machine 3KW 1 unit

BODOR Laser Tube Cutting Machine 6KW 1 unit

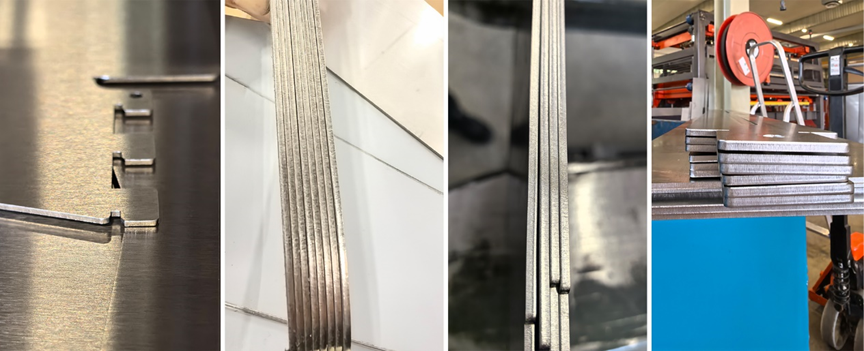

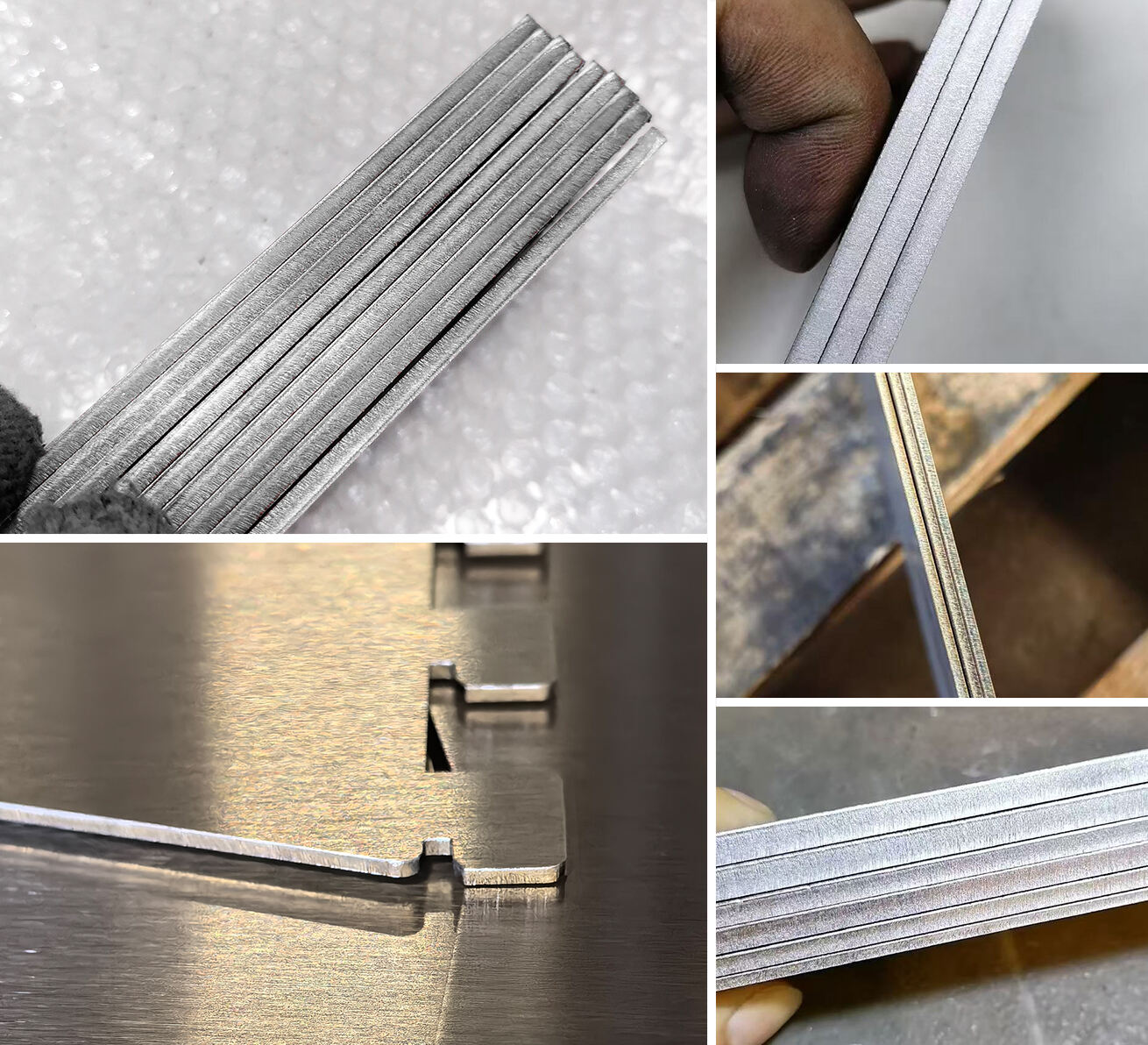

Cutting Work: 1.5mm~3mm thick stainless steel and galvanized sheet

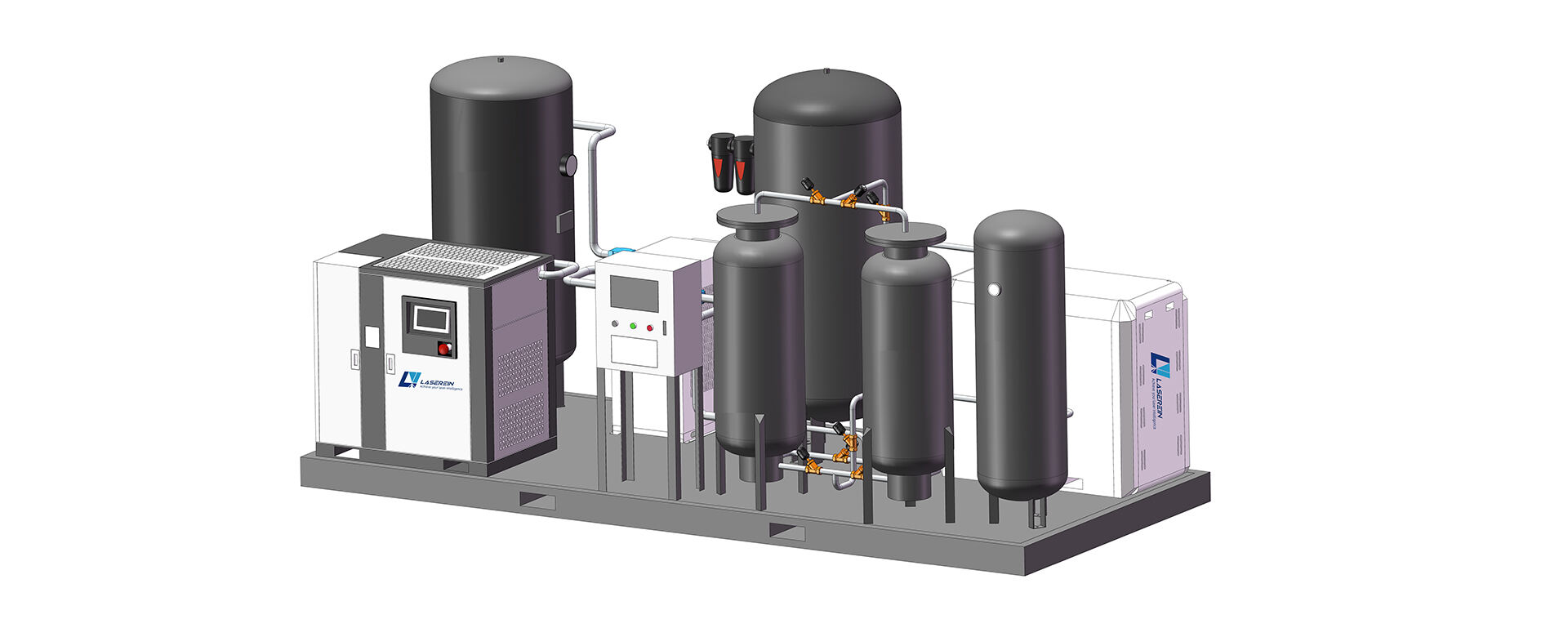

Gas Supply Solution : 1 unit of BCP40 ( 40m3/h nitrogen production on site)

Before the Investment:

*Using the cylinder nitrogen gas spending €200/Day for laser cutting work.

*Need labor work for the cylinder changing.

* Might confront with interruption of production because of gas lacking.

After the Investment:

*Stable 40m3/h 99.99% nitrogen production every day;

* 10- 30minutes for getting the required the gas supply every morning starting up the machine;

* Easy operation for machine start and stop, no special labor intervention when running the BCP40;

* Bright cutting surface no need a secondary treatment;

* No need for renting the cylinder gas pack (2 packs a week before the investment), saving rental and labor costs;

* Really cheap electricity cost for the machine: 0.8kwh/m3 nitrogen= €0.048/m3 nitrogen

Totally Hyllteknik saves €200/Day with Raysoar BCP40 Nitrogen Generator

BCP Series Products Introduction:

The BCP Series is an integrated high-pressure nitrogen generating system that provides reliable nitrogen sources with various

purity on-demand. By utilizing low-pressure dual-tower PSA (Pressure Swing Adsorption) filtration technology, it compresses ambient

air through a compressor, removes impurities via filters, and employs a refrigerated dryer for moisture removal, followed by PSA

and N2 compression to generate high-purity (99.99%) nitrogen at specified high pressures. This meets the requirements for premium

oxidation-free laser cutting applications.

Application

● High-quality stainless steel cutting scenarios, perfectly replacing liquid nitrogen

● Model M combines mixed gas cutting functionality, achieving premium cutting for carbon steel and aluminum alloys

Products Features:

● On-site gas generation enables oxidation-free cutting of various materials including carbon steel, galvanized sheet, stainless steel,

aluminum alloy, and brass, while also providing burr-free cutting for aluminum alloy and mixed-gas cutting for thick carbon steel.

● Replaces liquid nitrogen, saving 50%-90% compared to liquid nitrogen.

● Under regular maintenance of the air compressor, carbon molecular sieves boast a lifespan of up to 6-8 years.

● Run at 7*24 hours.