Moldel: BCP40/60/75/90/120/150

Solution for cutting stainless steel by producing 99.99% nitrogen on site

Cutting Material: Stainless Steel/ Carbon Steel/ Aluminum Alloy

Cutting Material Thickness: 1~25mm

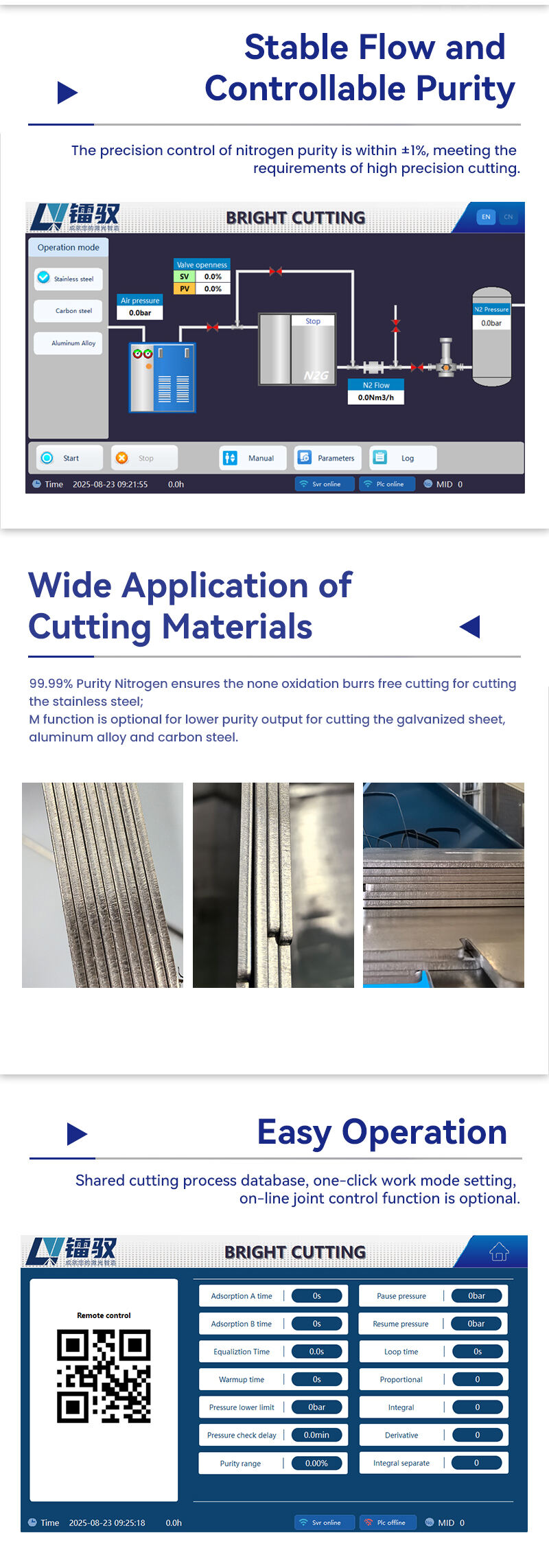

Features:

● High-quality cutting for stainless steel of thickness below 25mm, perfectly replacing liquid nitrogen;

● Remarkably reduce nitrogen usage costs by 50%-90%;

● 15 months pay back the investment;

● Stable 99.99% nitrogen producing without interruption the cutting work.

| Type | BCP40 | BCP60 | BCP75 | BCP90 | BCP120 | BCP150 |

| Total Power ( kw ) | 32 | 51 | 51 | 64 | 74 | 100 |

| Air Compressor Power(kw) | 22 | 37 | 37(Two-Stage) | 4 5 ( Two-Stage) | 5 5 (Two-Stage ) | 7 5 ( Two-Stage ) |

| Dimension(Skid-mounted) (mm)* | 4650*2000*2197 | 5400*2000*2500 | 5500*2000*2500 | 6000*2000*2500 | 6800*2000*2500 | 6800*2100*2500 |

| G.W.(Skid-mounted)(KG) | 3300 | 4500 | 4800 | 7300 | 8000 | 8400 |

| Dimension(without Skid) (mm)* | 8100*1000*2400 | 10350*1200*2450 | 10350*1300*2450 | 10300*1400*2700 | 11100*1600*2800 | 11700*1700*2800 |

| G.W.(Without Skid)(KG) | 2800 | 4020 | 4300 | 6300 | 7100 | 7400 |

| Adapting Laser Equipment Power(kw) | 3 | 6 | 6 | 12 | 20 | 30 |

| Max Flow Rate(m³/h) | 40 | 60 | 75 | 90 | 120 | 150 |

| Pressure(Mpa) | 2.5 | |||||

| Purity(%) | 99.99 | |||||

| Dew Point(℃) | -20 | |||||

| Power Supply(V/HZ) | 220/380V 3P50Hz(Customizable for other countries or regions) | |||||

| Pressure Vessel Standard | National standard(ASME U/ASME UM/NB/PED H/PEDH1 Customizable) | |||||

| *Mixed Gas Cutting | The M model can adjust nitrogen purity, and the system can switch to mixed gas cutting. | |||||