Customer Name: HanXin Metal Material Location: Shanghai, China Industry: Metal sheet and profiles processing Manufacture Equipment:Handheld welding machine 1.5KW 1 unit Cutting Work:Aluminum alloy Profiles Gas Supply Solut...

Share

Customer Name: HanXin Metal Material

Location: Shanghai, China

Industry: Metal sheet and profiles processing

Manufacture Equipment:Handheld welding machine 1.5KW 1 unit

Cutting Work:Aluminum alloy Profiles

Gas Supply Solution : Welding Mate WMP03 (3m3/h 99.99% nitrogen production on site) 1 Unit

This customer is a small scale sheet and profiles processing factory who owns a laser cutting machine, a

handheld welder, and an air compressor. Before the investment, the boss rented the cylinder argon as the gas

supply for his welding machine. After comparison,he found a welding mate cost him only a year’s renting

expenses. And because he has an air compressor already, all the investmentis just a unit of welding mate.

By investing this small nitrogen generator, the factory significantly improved welding efficiency, shortened

production cycles without cylinder changing.

Welding Mate Products Introduction:

Welding Mate is a compact nitrogen generator that ensures on-site production of nitrogen gas up to 10M3/H

(purity 99.99%). This all-in-one nitrogen generator, based on PSA technology, is an ideal choice for small and

medium-sized enterprises seeking safe,economical, convenient, and reliable nitrogen supply.

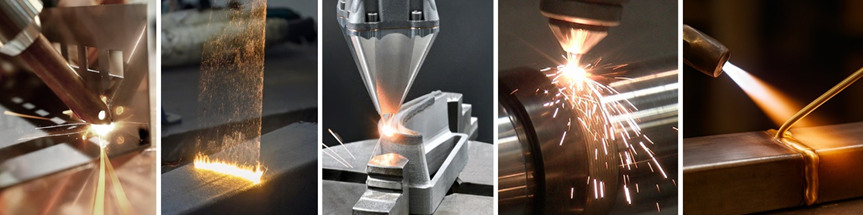

Application

● Laser welding, cleaning, metal 3D printing, heat treatment, brazing, etc.

Products Features:

● Lightweight and Flexible for Easy Integration: suitable for handheld laser welding machine applications

and can be easily integrated into welding equipment, whether built-in or externally mounted.

● Simple Operation with Stable and Efficient Performance: Fast startup with purity quickly meeting standards,

inteligent start-stop, automatic venting, and other functions ensure a continuous, stable, and eficient output of

99.99% purity, enabling fully automated operation.

● Safe, Convenient, and Low-Cost: Compared to gas cylinder or tank supply methods, it operates at low

pressure with no safety risks, eliminates the need for production interruptions to replace gas cylinders, and

reduces usage costs toapproximately 10% of cylinder gas.