Customer :high-end construction machinery manufacturer Location: Shandong, China Industry: Construction Machinery & Heavy Equipment Manufacturing Manufacture Equipment:Laser Cutting Machine 30KW 1 unit ...

Share

Customer :high-end construction machinery manufacturer

Location: Shandong, China

Industry: Construction Machinery & Heavy Equipment Manufacturing

Manufacture Equipment:Laser Cutting Machine 30KW 1 unit

Laser Cutting Machine 40KW 1unit

Laser Cutting Machine 80KW 1 unit

Cutting Work:8-25MM carbon steel

Gas Supply Solution : 4 units of FCP (100m³/h nitrogen production on site)

5 units of FCP (150m³/h nitrogen production on site)

Before the Investment:

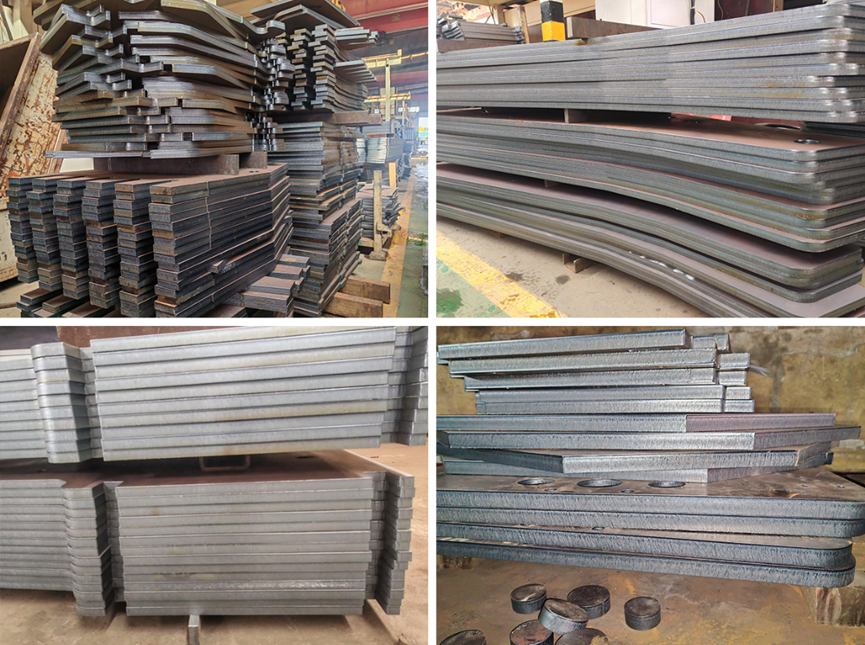

Before adopting our equipment, the factory mainly relied on air cutting for 12–40 mm carbon steel plates on

high-power laser systems. This often resulted in oxidized cut surfaces, rough edges, and heavy slag adhesion,

which negatively affected subsequent welding and painting processes. In addition, limited cutting speed and

increased post-processing workload restricted overall production efficiency.

After the Investment:

After investing in our FCP nitrogen generators and switching to a 94%–96% N₂–O₂

mixed gas supply, cutting performance improved significantly. Cut surfaces became clean and oxidation-free,

slag was greatly reduced, and both cutting speed and stability were enhanced. High-power laser systems

were able to operate at optimal performance, resulting in higher quality and improved production efficiency.

FCP Series Products Introduction:

Mixed gas cutting employs a specific ratio of nitrogen-oxygen mixture as the laser assist cutting gas, leveraging

the advantages ofeach component gas (nitrogen for high-speed cutting and oxygen for burr-free cutting) by

combining them into a single cutting stream.This method enables rapid cutting with minimal burrs, significantly

improving the cutting quality for medium-to-thick low-carbon steeland aluminum alloys while achieving higher

cutting speeds than pure nitrogen. The burring issues encountered when using purenitrogen or air cutting a

are minimized or eliminated.

Advantages of Mix-Gas Cutting:

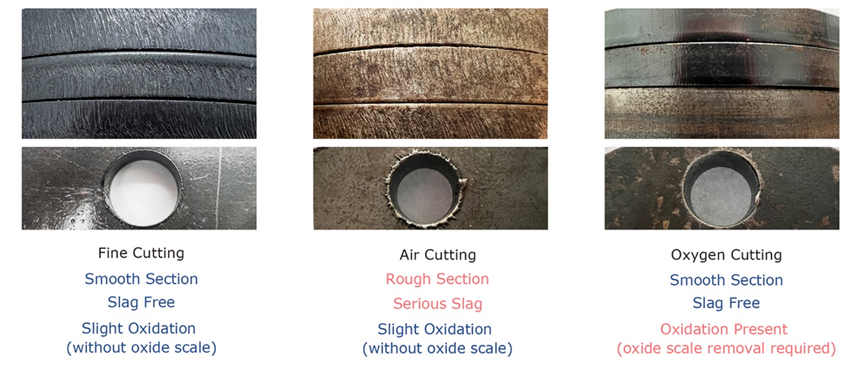

● Improves cutting quality of ordinary steel, reducing burrs to <3% of material thickness.

● Higher surface finish compared to air cutting.

● Significantly increases cutting speed compared to oxygen cutting of high-power medium-thick carbon steel plates.

● Offers a cost advantage compared to liquid nitrogen cutting.

Fine Cutting VS Air Cutting vs O2 Cutting

Application

● Heavy cutting work for carbon steel (replacing the air cutting or liquid nitrogen cutting)

● Burr-free cutting of aluminum ally.

Products Features:

● Compared to liquid nitrogen and liquid oxygen dual-gas mixing systems, it achieves up to 70% savings,

delivers rapid returns, with an average ROI payback period of 12-18 months.

● Easy maintenance, with a system lifespan of 6-8 years requiring regular maintenance.

● LOT-enabled functionality, featuring exclusive SMART-REIN for remote monitoring via mobile devices.

It intelligently selects operational modes based on factory conditions to optimize energy consumption.

● Equipment interconnectivity and collaboration capabilities, enabling coordinated control with machine

tools equipped with the BOCHU system customizable functions.