Problem Phenomenon |

Quick Judgment Method |

Emergency Handling Steps |

Preventive Measures |

Nozzle Clogging |

1. Obvious decrease in shielding gas flow during welding with laser emission; 2. Weld oxidation and porosity occur; 3. Slag accumulation is visible at the nozzle outlet |

1. Turn off the equipment power and gas circuit, wait for the nozzle to cool down; 2. Use a special pin to clear the nozzle outlet (avoid scratching the inner wall); 3. Purge the inner wall with dry compressed air; 4. Bake stubborn slag at low temperature before cleaning |

1. Maintain a 1-3mm distance between the nozzle and the base metal during welding; 2. Use 99.99% high-purity shielding gas; 3. Clean the nozzle every 30 minutes of welding |

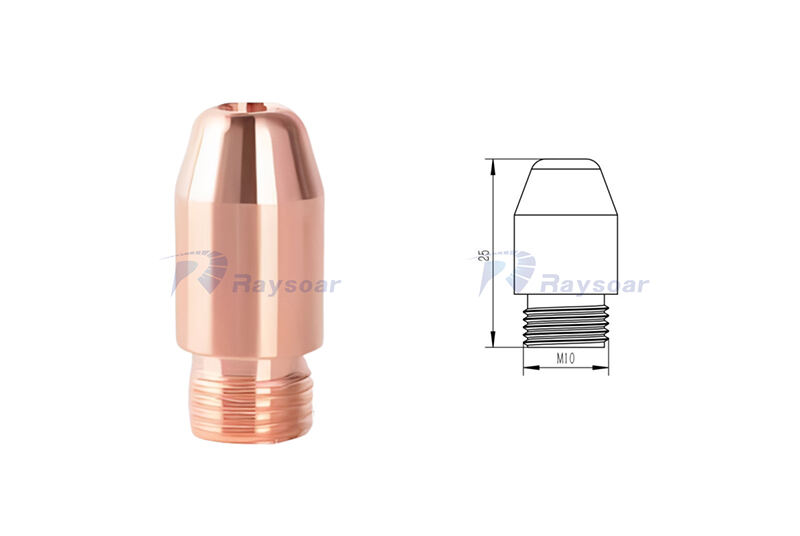

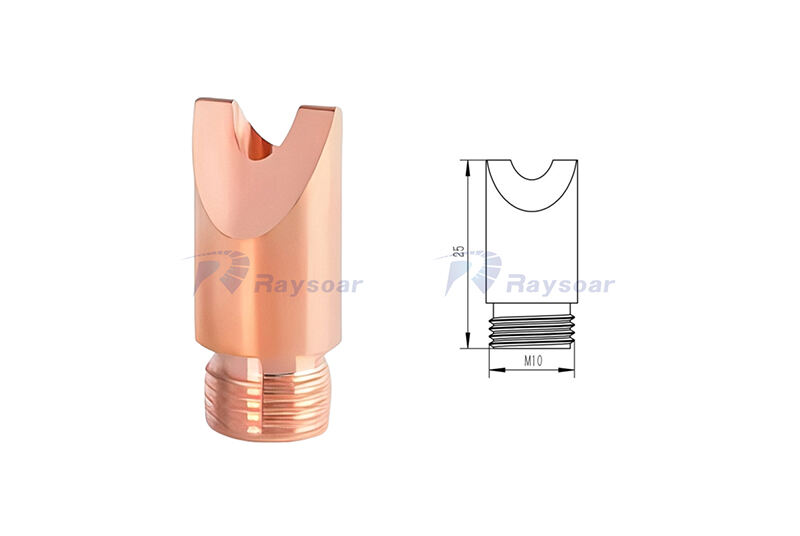

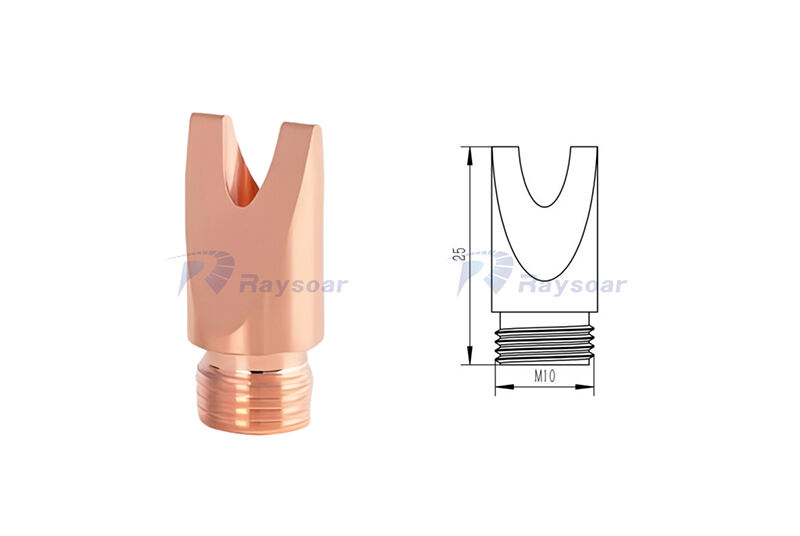

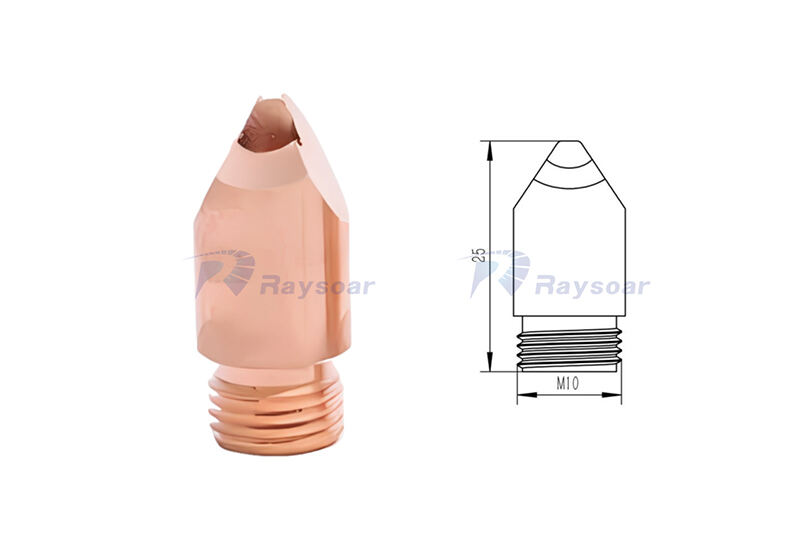

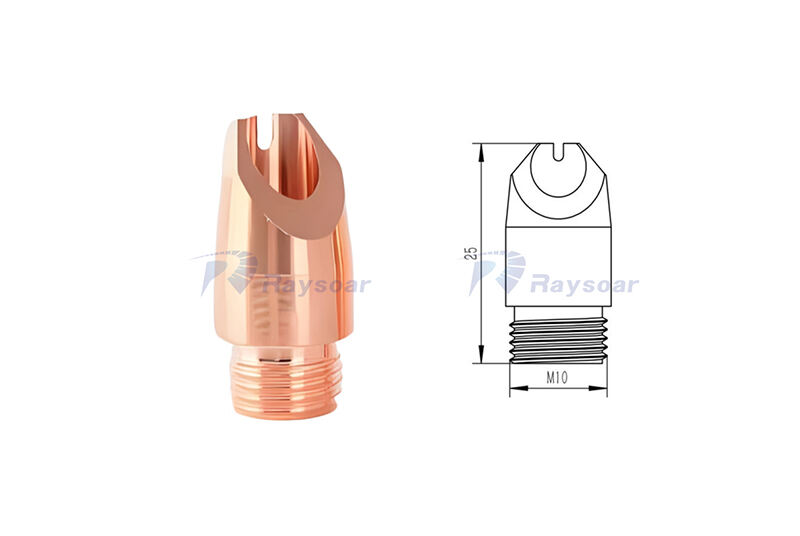

Nozzle Wear/Deformation |

1. Collision marks on the nozzle outlet edge and irregular aperture; 2. Uneven weld width and offset welding; 3. Abnormal shielding gas coverage range |

1. Stop using the deformed/worn nozzle and replace it with a new one of the same specification; 2. Calibrate the alignment between the nozzle center and laser focus after installation |

1. Avoid nozzle collision with the base metal/fixture during operation; 2. Choose wear-resistant nozzles made of copper-chromium-zirconium material; 3. Disassemble and assemble with special tools, tighten according to specified torque |

Nozzle Air Leakage/Poor Shielding Effect |

1. Weld surface turns black due to oxidation and dense porosity appears; 2. Continuous air bubbles around the nozzle are visible in the water immersion test; 3. Large fluctuation of shielding gas pressure gauge value |

1. Check the gasket between the nozzle and the gun body, replace if aging/damaged; 2. Tighten the gas circuit connector and reinstall the nozzle; 3. Directly replace the damaged nozzle |

1. Check the gasket status weekly and replace it regularly every month; 2. Perform 30-second gas circuit leak test before welding; 3. Avoid sudden cooling and heating of the nozzle at high temperature |

Excessively High Nozzle Temperature |

1. The outer wall of the nozzle is hot and even discolored due to oxidation; 2. The temperature at the shielding gas outlet is high, intensifying weld oxidation; 3. The welding gun alarms for overheating |

1. Immediately stop welding, turn off the laser, and keep the cooling system running for 5-10 minutes; 2. Clean the water cooling pipeline (water-cooled type) or air duct (air-cooled type); 3. Replace the overheated and deformed nozzle |

1. Do not weld continuously for more than 15 minutes, cool down at intervals; 2. Regularly clean scale in the cooling water pipeline; 3. Adjust laser power according to the thickness of the base metal |

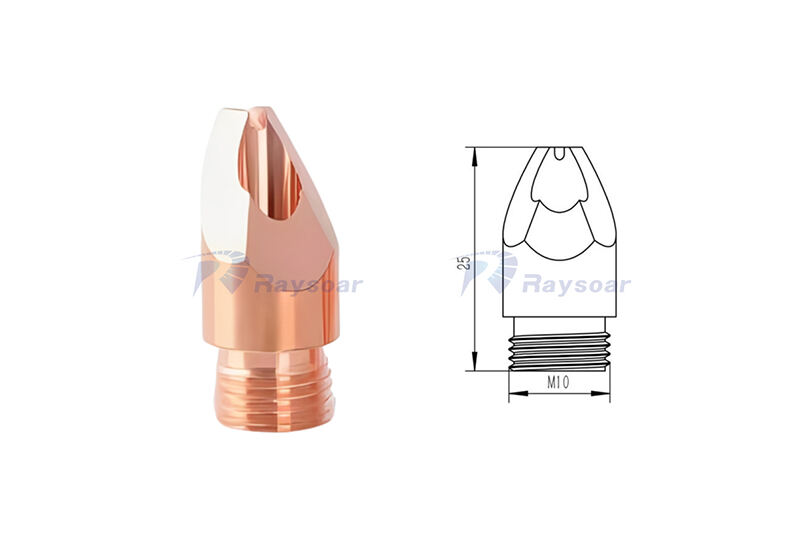

Misalignment Between Nozzle and Welding Wire |

1. The welding wire deviates from the weld center, resulting in incomplete fusion; 2. Misalignment between the laser spot and the welding wire position, increasing welding spatter; 3. Poor weld formation and undercut |

1. Remove the nozzle and re-calibrate the gun center; 2. Check the connection between the wire feed tube and the nozzle, adjust to the aligned state; 3. Directly replace the worn nozzle |

1. Perform alignment calibration after replacing the nozzle each time; 2. Fix the position of the wire feed tube to avoid bending and offset; 3. Regularly check the stability of the wire feed mechanism |