ThePure Air Cutting Basic Series is an air cutting system developed for low- to mid-power laser cutting equipment (6 kW–12 kW), this system delivers high energy efficiency, stable air pressure, and precisely controlled gas quality.

It can be quickly integrated into customers’ existing systems, providing a fast, economical, and reliable solution for achieving stable air cutting processes.

Exceptionally low specific power consumption, exceeding China Class 1 energy efficiency standards.

Wide load adjustment range from 10% to 100% ensures high efficiency under varying operating conditions.

Extremely low leakage rate of 0.15%, achieved through nano-coating sealing technology.

Ultra-clean air quality with oil content ≤ 0.0005 ppm (oil-free version), meeting high-purity air requirements.

Compact structure with fewer components and minimal wear parts, making maintenance simple and efficient.

Routine servicing can be completed without specialized technicians.

Compared with traditional air compressors, maintenance intervals are extended and overall maintenance costs are

significantly reduced, effectively lowering long-term operating expenses.

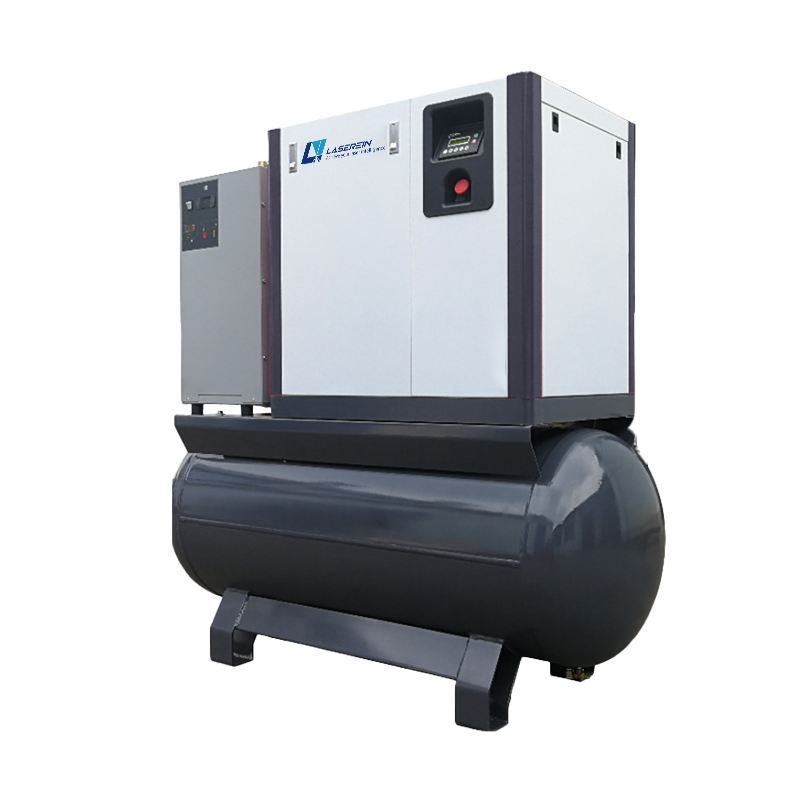

Equipped with a resin-coated anti-rust air tank, effectively preventing corrosion and secondary contamination, ensuring

clean and reliable compressed air supply.

Features an intelligent control system with a touchscreen interface, providing real-time protection functions including

overload protection, over-temperature protection, phase-loss protection, and high/low pressure protection.Supports

remote monitoring. Customized models allow users to access equipment status via mobile APP or PC, enabling

remote fault diagnosis and operation & maintenance management, significantly improving management efficiency.

The scroll compressor features excellent structural balance and minimal torque fluctuation, ensuring smooth and stable

operation.Optimized airflow channel design and high-efficiency silencers significantly reduce overall noise levels,

making it noticeablyquieter than conventional screw air compressors of the same capacity.

Low Noise: 50–65 dB(A)

High Energy Efficiency: Energy savings of up to 13%–18.6% compared with screw compressors

Ultra-Low Oil Content: As low as 0.03 ppm, effectively protecting laser cutting systems and optical lenses from contamination

|

|

|

|

Air Class: ISO 8573-1,Class1-2-0 No water mist, no oil stains, no residual particles. |

Air Class: Normal dryness level Traditional Air Treatment slight residual particles |

Air Class: Normal dryness level Traditional Air Treatment Slight water mist, slight oil stains |

| Item | PAB10 | PAB15 | PAB20 | PAB30 |

|---|---|---|---|---|

| Model | PAB10 | PAB15 | PAB20 | PAB30 |

| Air Compressor Power (kW) | 7.5 | 11 | 15 | 22 |

| Flow Rate (m³/h) | 48 | 60 | 78 | 120 |

| Weight (kg) | 270 | 420 | 450 | 600 |

| Air Receiver Tank (L) | 230 × 1 | 400 × 1 | 400 × 1 | 250 × 2 |

| Pressure (MPa) | 1.6 | 1.6 | 1.6 | 1.6 |

| Dimensions (L × W × H, mm) | 1400 × 500 × 1110 | 1700 × 750 × 1500 | 1700 × 740 × 1630 | 2100 × 850 × 1680 |

| Structure | Integrated | Integrated | Integrated | Integrated |

| Dew Point (°C) | -20 | -20 | -20 | -20 |

| Air Quality | ISO 8573-1 Class 1-3-1 | ISO 8573-1 Class 1-3-1 | ISO 8573-1 Class 1-3-1 | ISO 8573-1 Class 1-3-1 |

| Power Supply (V/Hz) | 220/380V, 3P, 50Hz (Customizable for other countries or regions) | Same | Same | Same |

| Compatible Laser Power Range (kW) | 3–6 kW (Tube Cutting) | ≤3 kW | ≤6 kW | ≤12 kW |