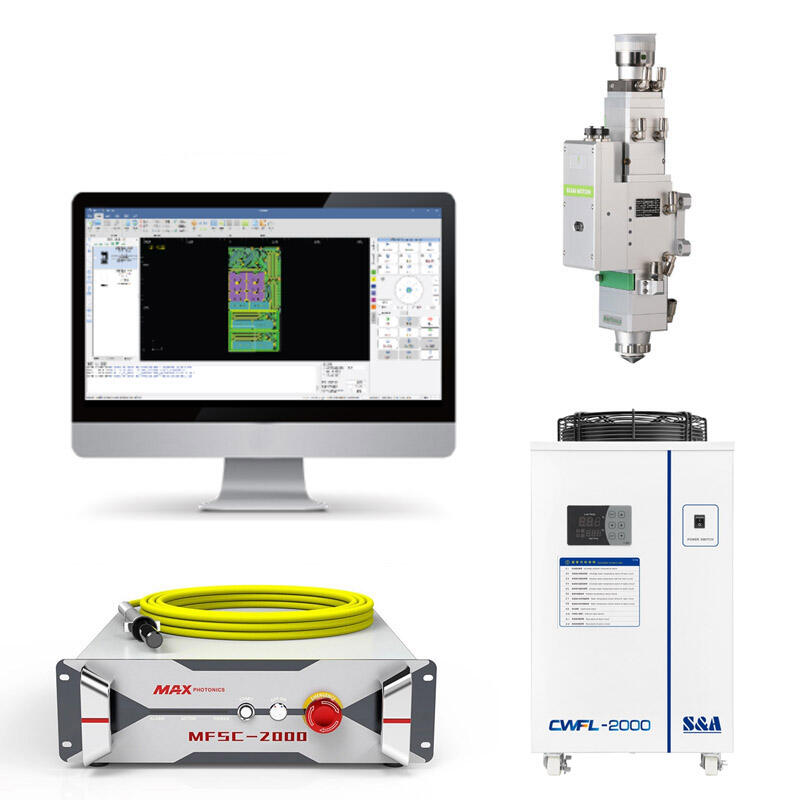

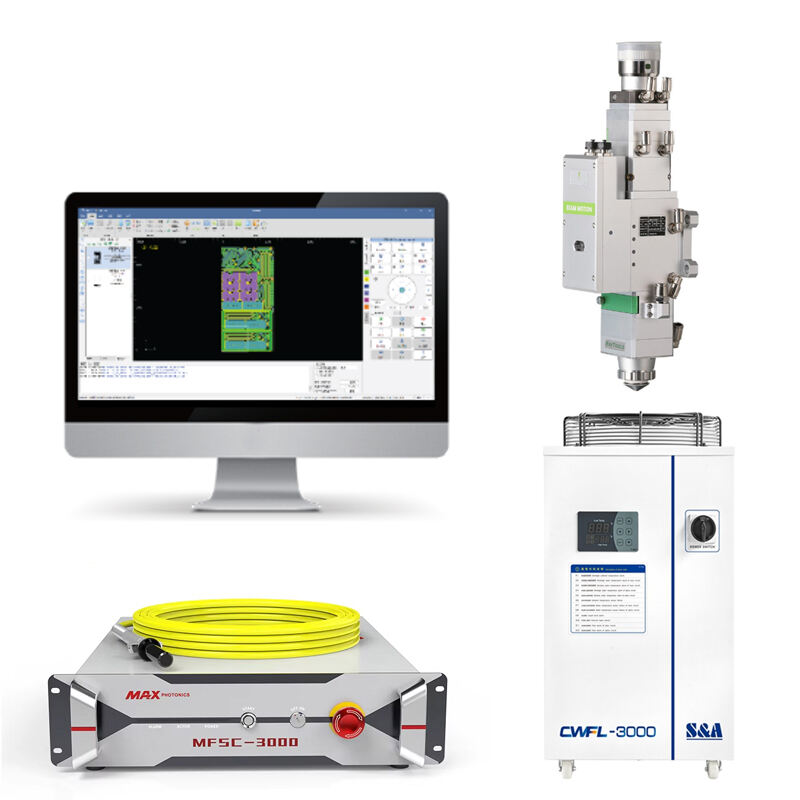

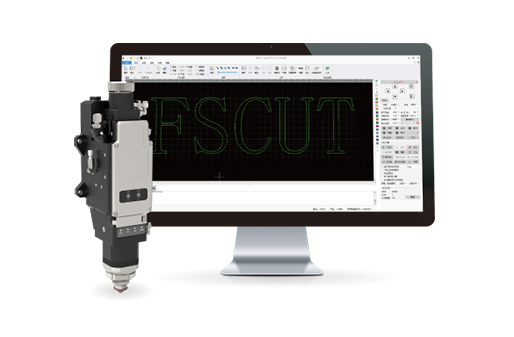

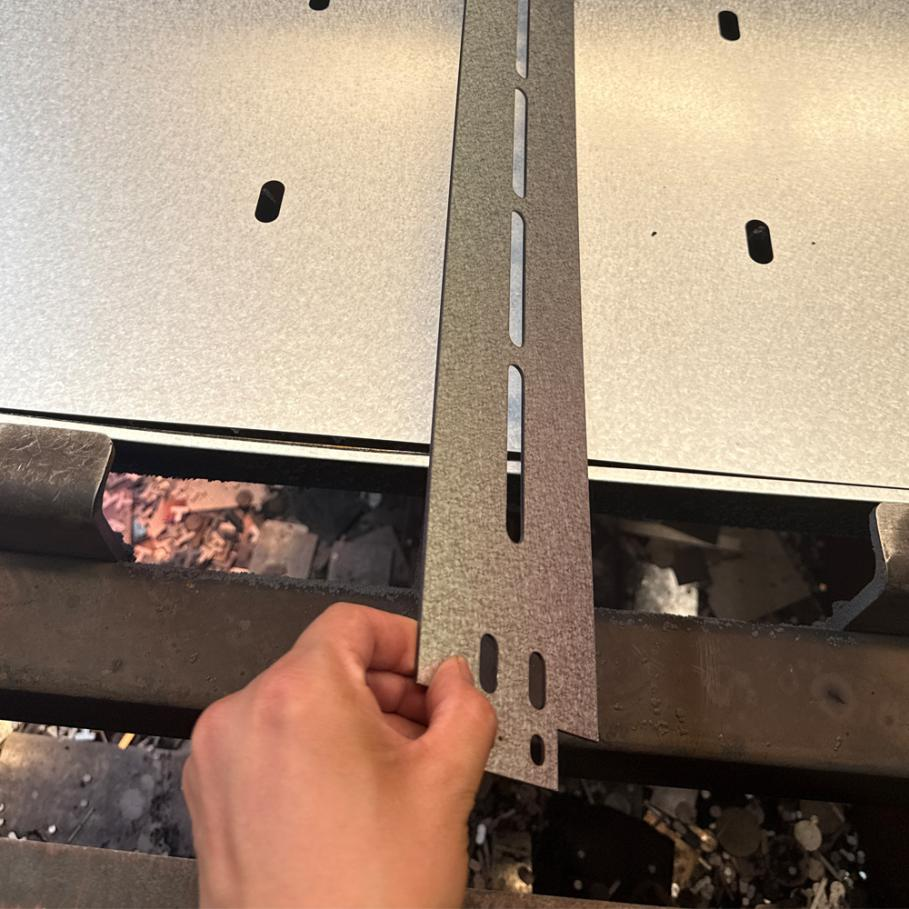

Maximize Your Laser Operations with Our Fiber Laser Controller

The Fiber Laser Controller from Shanghai Raysoar Electromechanical Equipment Co., Ltd. is engineered to enhance the efficiency and precision of your laser applications. With over 20 years of experience in the industrial laser field, we understand the critical role that a high-quality controller plays in the performance of laser machines. Our controllers offer seamless integration, user-friendly interfaces, and robust support for various laser types, ensuring that you achieve optimal results in your operations. The advanced technology embedded in our controllers allows for precise control and monitoring, which leads to improved productivity and reduced operational costs.