Maximize Your Laser Efficiency with Our Fiber Laser Control Board

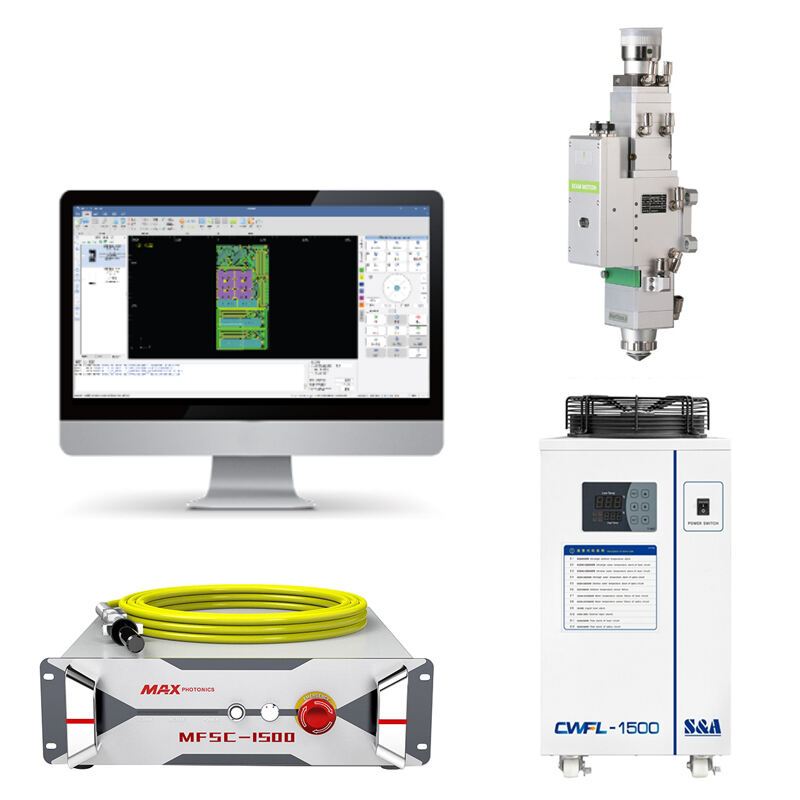

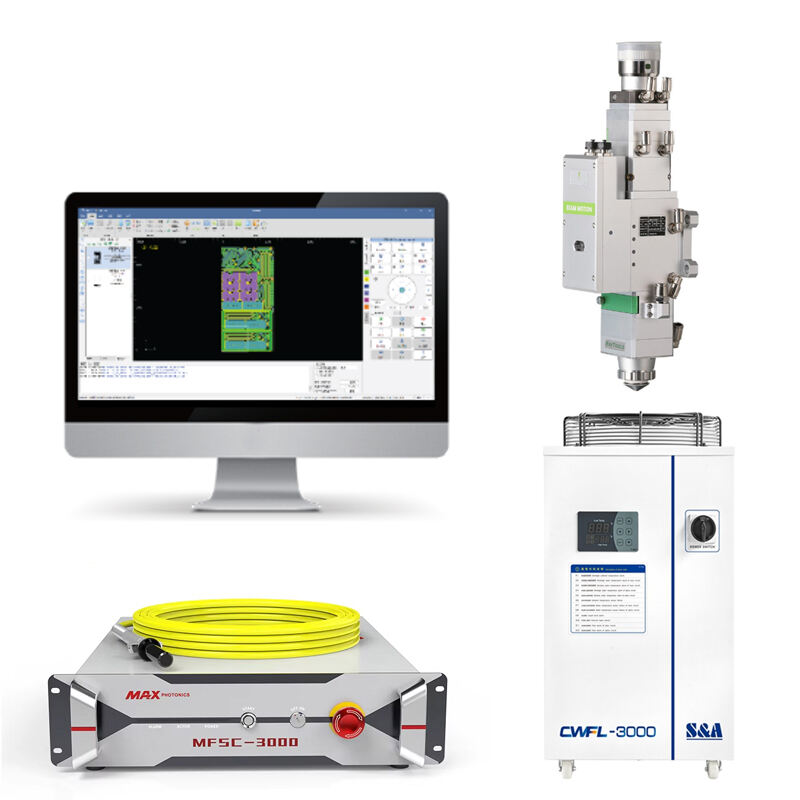

The Fiber Laser Control Board from Shanghai Raysoar Electromechanical Equipment Co., Ltd. is designed to optimize the performance of modern laser industrial equipment. With over 20 years of experience in the laser application field, our control board enhances precision, reliability, and productivity in laser operations. It supports various laser machine models and offers seamless integration with existing systems. Key advantages include improved operational efficiency, reduced downtime, and advanced features that facilitate easy maintenance and upgrades. Our control board is not just a component; it is a solution that empowers businesses to achieve superior results in their laser applications.