Fine Cutting Ultra Series

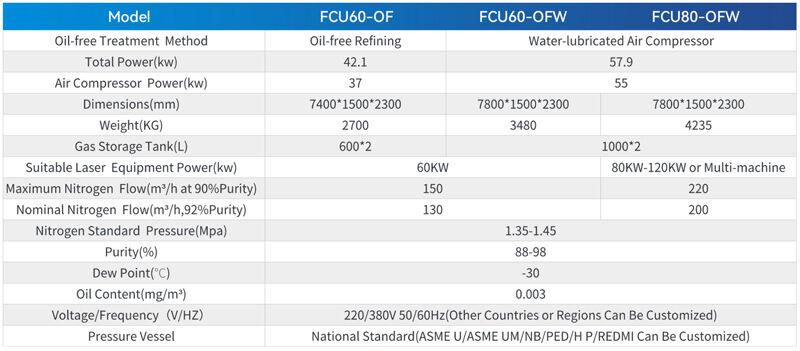

Product Type: FCU12/30/40/60/60P

Cutting Material: Carbon steel plates/ galvanized plates/ high-quality aluminum alloy

Application

● Scenarios with high carbon steel cutting volume (replacing air cutting or liquid nitrogen cutting)

● Aluminum alloy burr-free cutting scenarios

Froduct Introduction

The Fine Cutting Ultra series adopts modular PSA (Pressure Swing Adsorption) filtration technology, upgrading the traditional dual-tower system to a modular design, which features a compact structure, small footprint, and easy mobility for on-site installation and maintenance. The modular nitrogen generator is equipped with ES energy-saving function, which adjusts the cycle time based on actual load to ensure full utilization of molecular sieves during each adsorption process, thereby reducing purge gas consumption and achieving energy-saving goals. Additionally, the air compressor employs two-stage compression technology, significantly improving efficiency and reliability compared to single-stage system while effortlessly achieving high pressure with minimal pressure fluctuations.

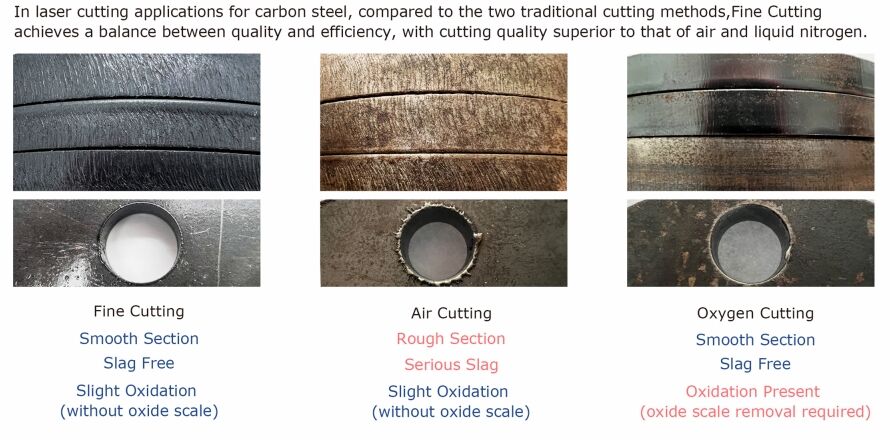

Advantages of Mixed Gas Cutting

● Improves cutting quality for ordinary steel, reducing burrs to <3% of material thickness;

● Higher surface finish compared to air cutting;

● Significantly increases cutting speed compared to high-power oxygen cutting for medium-thick carbon steel plates;

● More cost-effective compared to liquid nitrogen cutting.

Product Features

● Dual optimization of air compression and nitrogen production energy efficiency, achieving over 30% energy savings compared to similar products

● Comprehensive upgrades in electrical/pneumatic/material/pipeline components, aligning with international top-tier quality standards

Technical Specifications

Cutting Quality Comparison Fine Cutting VS Air and Oxygen