Customer Name: TIERENXINWEI Location: Guangdong Province, China Industry: Mechanical manufacturing Manufacture Equipment:Fiber Laser Cutting Machine 30kw 1 unit Cutting Work: 10mm~25mm carbon steel Q235 Q355 Gas Supply S...

Share

Customer Name: TIERENXINWEI

Location: Guangdong Province, China

Industry: Mechanical manufacturing

Manufacture Equipment:Fiber Laser Cutting Machine 30kw 1 unit

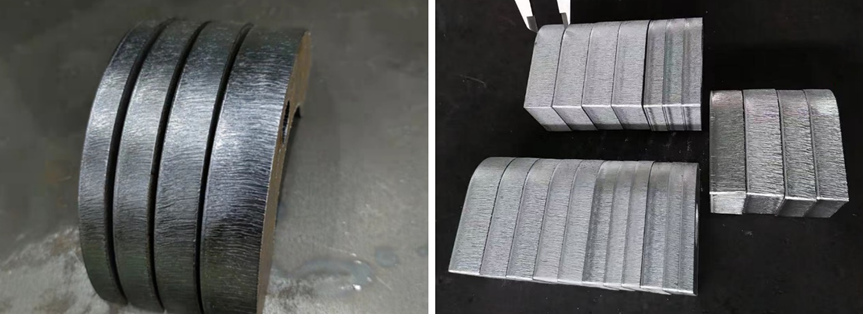

Cutting Work: 10mm~25mm carbon steel Q235 Q355

Gas Supply Solution : FCS180 1 unit ( 180m3/h N2 O2 Mix Gas production on site)

Before the Investment:

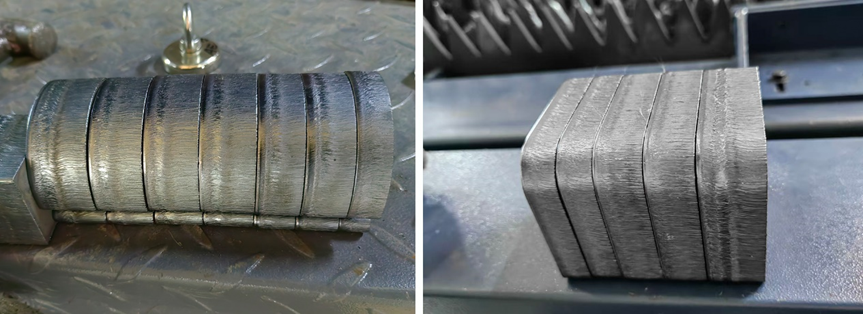

Client used liquid nitrogen and liquid Oxygen as the assist gas for laser cutting work, but still experienced issues such as rough cut

surfaces slag adhesion and inconsistent texture. High liquid nitrogen consumption costs is also the important reason for this investment.

After the Investment:

The cutting results improved immediately:smoother surfaces, finer textures, significantly reduced slag and more consistent

quality in small holes and corners.

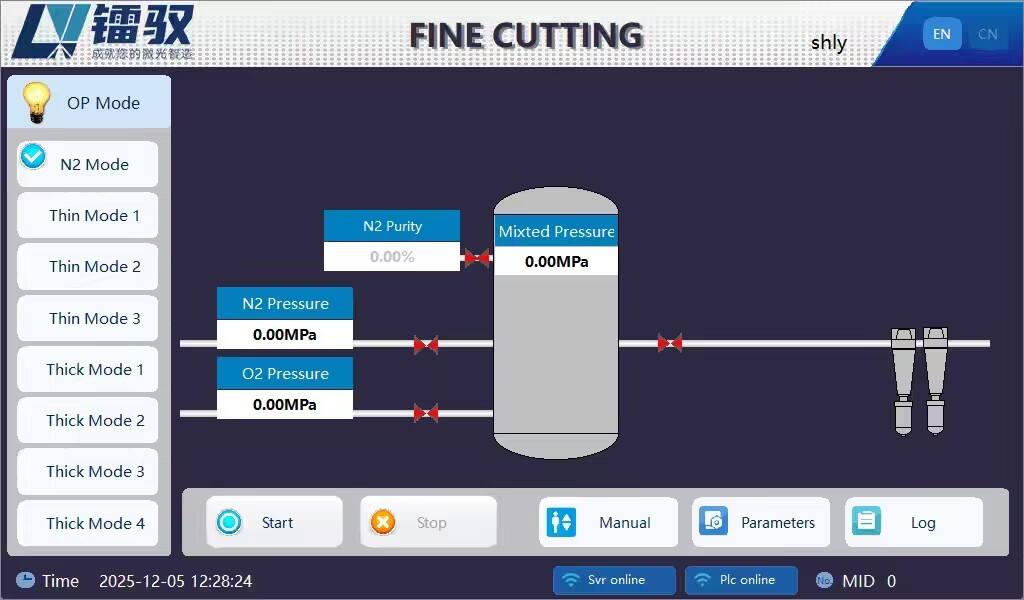

By selecting of corresponding process on the control panel according to different cutting materials, the FCS180 produces

86%~98% purity nitrogen 180m3/h on site, provide stable and supreme mixed cutting gas to achieve best cutting efficiency

and quality.

FCS Series Products Introduction:

Fine Cutting Spirit Series is a gas mixing device designed for mixed gas cutting processes,used in scenarios where high flow and

fluctuating mixed gas is required as an assist gas in laser cutting. It consists of a gas mixer and a premixing tank (option for high

flow rate cutting). Featured with further purified gas source of nitrogen and oxygen, the device also helps to greatly reduce the

risks of lens and cutting head pollution caused by air cutting.

Application:

● High-quality stainless steel cutting scenarios, perfectly replacing liquid nitrogen

● Model M combines mixed gas cutting functionality, achieving premium cutting for carbon steel and aluminum alloys

Products Features:

● Integrated Electric-pneumatic proportional valve manifold provides infinitely variable settings

● Equipped with a local control unit

● Adjustable remotely via Ethernet or analog input

● Mobile APP can monitor in real time or set the working mode with one key

● Simple and intuitive operation: No certified personnel required

● Unaffected by fluctuations in gas supply pressure