How to choose a fiber laser source for your laser cutting machine?

Guidelines for Choosing a Fiber Laser Source for Your Laser Cutting Machine

Fiber laser source is the core power source of laser cutting machine, its performance directly determines the machining precision, efficiency, applicable material range and long-term operation stability of the machine.

It's Not Just a Purchase, It's a Strategic Investment

Let's be real. Buying a fiber laser source feels overwhelming. You're bombarded with specs, brand claims, and price points that all seem to blur together. But here's the key mindset shift: you're not just buying a bright light in a box. You're investing in the future productivity, capability, and profitability of your entire operation. The right choice becomes a workhorse that drives throughput, handles tougher jobs, and pays for itself faster. The wrong choice? A source of constant headaches, unexpected downtime, and costs that quietly drain your bottom line. This guide cuts through the noise. We'll use clear data, practical comparisons, and real-world considerations—straight from industry insights—to help you make a decision that makes technical and business sense for your shop.

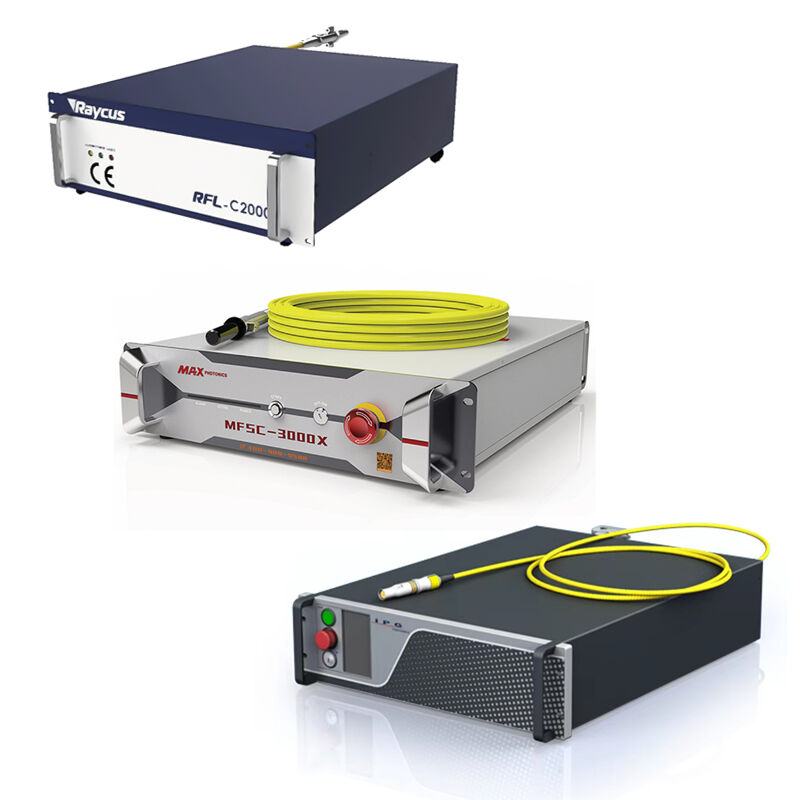

Advantages and Disadvantages of IPG LaserSourceandDomestic MainstreamLaserSourceRAYCUS /MAX

When we discuss the fiber laser source, the famous brand IPG, Raycus, MAX will jump into our mind. Here below let’s make a comparison of these fiber laser sources, which might help you make a decision of which brand you should purchase for your laser cutting machine.

IPG fiber laser source leads in high-power stability, beam quality, core component self-sufficiency, and lifespan, making them suitable for high-end precision and extreme operating conditions. Domestic mainstream brands (e.g., Raycus, MAX) excel in cost-effectiveness, localized services, and rapid iteration, demonstrating significant advantages in medium-low power and general industrial applications, while accelerating their progress in high-power segments.

1. Core Performance and Technology Comparison (2025 Data)

|

Comparison Dimension |

IPG Fiber Laser |

Mainstream Domestic Fiber Lasers (Raycus/Maxphotonics/JPT, etc.) |

|

Beam Quality (M²) |

M² < 1.1 for single-mode products, < 1.3 for higher-order modes; outstanding focusing accuracy and cutting/welding consistency |

1.2–1.5 for medium-low power, 1.3–1.6 for high power; meets most industrial requirements, but gaps remain in precision scenarios |

|

Electro-optical Conversion Efficiency |

~40%–45% for standard models, up to 50%+ for ECO series; significant long-term energy-saving effect |

~35%–40% for medium-low power, 32%–38% for high power; gap with IPG narrowing, but slight fluctuation under extreme working conditions |

|

Service Life & Stability |

Pump diode lifespan > 100,000 hours; all-solid-state fiber-to-fiber design without free-space optical components; stable under high temperature/humidity/vibration; longer MTBF |

60,000–80,000 hours for medium-low power, 50,000–70,000 hours for high power; slightly inferior stability under high-load and extreme environments; partial reliance on imported core components |

|

Core Components |

Fully self-developed pump sources, high-power gain fibers and optical devices; vertical integration brings advantages in cost and quality control |

Rising localization rate of pump sources and optical devices, but high-power gain fibers and special fibers still rely on imports; yield and consistency to be improved |

2. Cost, Service & Market Positioning

|

Comparison Dimension |

IPG Fiber Laser |

Mainstream Domestic Fiber Lasers |

|

Procurement Cost |

High-end positioning, 20%–50% more expensive than domestic counterparts of the same power; launched E-series economical products to narrow the price gap |

20%–40% cheaper for medium-low power, 30%–50% cheaper for high power; outstanding cost-performance ratio; further cost reduction through large-scale production |

|

Maintenance & Spare Parts |

Modular design for easy maintenance; long service life of spare parts; however, high spare part prices, long delivery cycles and extended service response time |

Sufficient local inventory of spare parts, low maintenance cost and fast response (on-site service within 24–48 hours); after-sales system adapted to the rhythm of domestic factories |

|

Market Positioning |

High-end scenarios with stringent requirements for quality and stability, such as aerospace, precision electronics, high-end automotive manufacturing, thick plate cutting/welding |

General sheet metal cutting, mid-to-low-end welding, laser marking, 3C electronics and other medium-low power, mass-production industrial scenarios prioritizing cost-performance ratio |

|

R&D & Iteration |

Strong patent barriers (300+ core patents); vertically integrated R&D focusing on ultra-high power, ultrafast lasers and wavelength expansion |

Rapid growth in R&D investment and patent quantity; fast iteration in medium-power segment focusing on cost optimization and local adaptation |

Fiber Laser Source Selection Recommendations

Based on the context, this refers to recommendations for selecting laser equipment types, particularly in high-end precision, aerospace, thick-plate high-power cutting, and welding applications.

For high-end precision, aerospace, thick-plate high-power cutting, and welding: IPG is the preferred choice, ensuring yield with stability and beam quality.

For general sheet metal cutting, mid-to-low-end welding, 3C electronics, marking, and other mid-to-low power mass production scenarios: domestic mainstream brands are recommended to balance cost and efficiency.

For limited budget but requiring high power: consider domestically produced mature models, paired with high-quality optical components and process optimization to enhance performance.

IPG maintains its leadership in high-power, precision, and extreme-condition applications through core technologies and full industrial chain advantages. Domestic brands, leveraging cost-effectiveness, localized services, and rapid iteration, are rapidly replacing IPG in mid-to-low-power and general industrial scenarios. With breakthroughs in domestically produced high-power core components and the rollout of IPG's cost-effective product lines, competition in the mid-to-high-power market will intensify, ultimately determined by customers' comprehensive trade-offs between quality, cost, and service.

What factors shall we consider when replacing the old fiber laser source?

For replacing the old fiber laser source with the same power, you must confirm the following specifications:

1.Fiber Core Diameter: Impacts focusability. Don't assume a new source uses the same core size as your old one.

2.Connector Type (QBH, QCS, etc.): This must be an exact physical match for your cutting or welding head. An adapter is not a solution; it's a point of potential failure and power loss.

3.Fiber Length: Ensure the delivered cable length is sufficient for your machine layout without excessive bending.

For upgrading your fiber laser cutting machine to a higher power level, you must take the following factors into your consideration:

Moving from, say, 3kW to 12kW? The laser source is only part of the cost. Your chiller must have the cooling capacity (in kW of heat removal) to handle the massive increase in waste heat. Your cutting head and its consumables (nozzles, protective windows) must be explicitly rated for the higher power density. Overlooking this will result in immediate damage, poor performance, and negate any benefit of the new source.

The Deal-Breaker: Warranty, Service, and True Total Cost of Ownership

The smartest buyers calculate Total Cost of Ownership (TCO). TCO = Purchase Price + Energy Costs + Maintenance + Repairs + (Cost of Downtime). The last factor is often the most expensive.

This is where local support and warranty become your most critical insurance policy. Before signing anything, you must have a crystal-clear answer to: "What happens when something goes wrong?"

The Ghost Supplier Risk: As noted in common industry pitfalls, buyers often get a "great deal" from a vendor with no local presence, only to find themselves completely stranded when they need technical support or a spare part. The supplier is unreachable, and no one else will touch the unfamiliar, unsupported system.

To find a reliable supplier is very important when you decide to import the parts from other countries for your laser cutting machine. From cheap consumables such as nozzles, protect windows, ceramic nozzle holders to expensive functional parts such as the laser cutting head, controller, fiber laser source, it is wise to find a professional supplier who can support you on technical problems and after-sales service for any defective products.

Raysoar's Role: Your Partner for Integrated Productivity Assurance

At Raysoar, we solve the very challenges outlined above. We know that selecting the optimal laser source is just the first step. Success depends on flawless integration and unwavering support.

We act as your technical consultant, helping you navigate the data-driven choice between premium stability and value-driven performance, ensuring the specification aligns perfectly with your application and business model. More importantly, we provide Integration Certainty. We manage the entire compatibility checklist—verifying fiber interfaces, control system handshakes, and auxiliary system requirements—to ensure your new source is a plug-and-play productivity boost, not a project nightmare.

Ultimately, we provide Productive Assurance. Our commitment is to be your long-term partner, offering reliable access to service, expertise, and support. We believe in solutions that deliver not just a powerful beam, but predictable, profitable output for years to come. With Raysoar, you're not just buying a laser source; you're investing in a foundation for growth with a team dedicated to keeping your production lights on and your business moving forward.