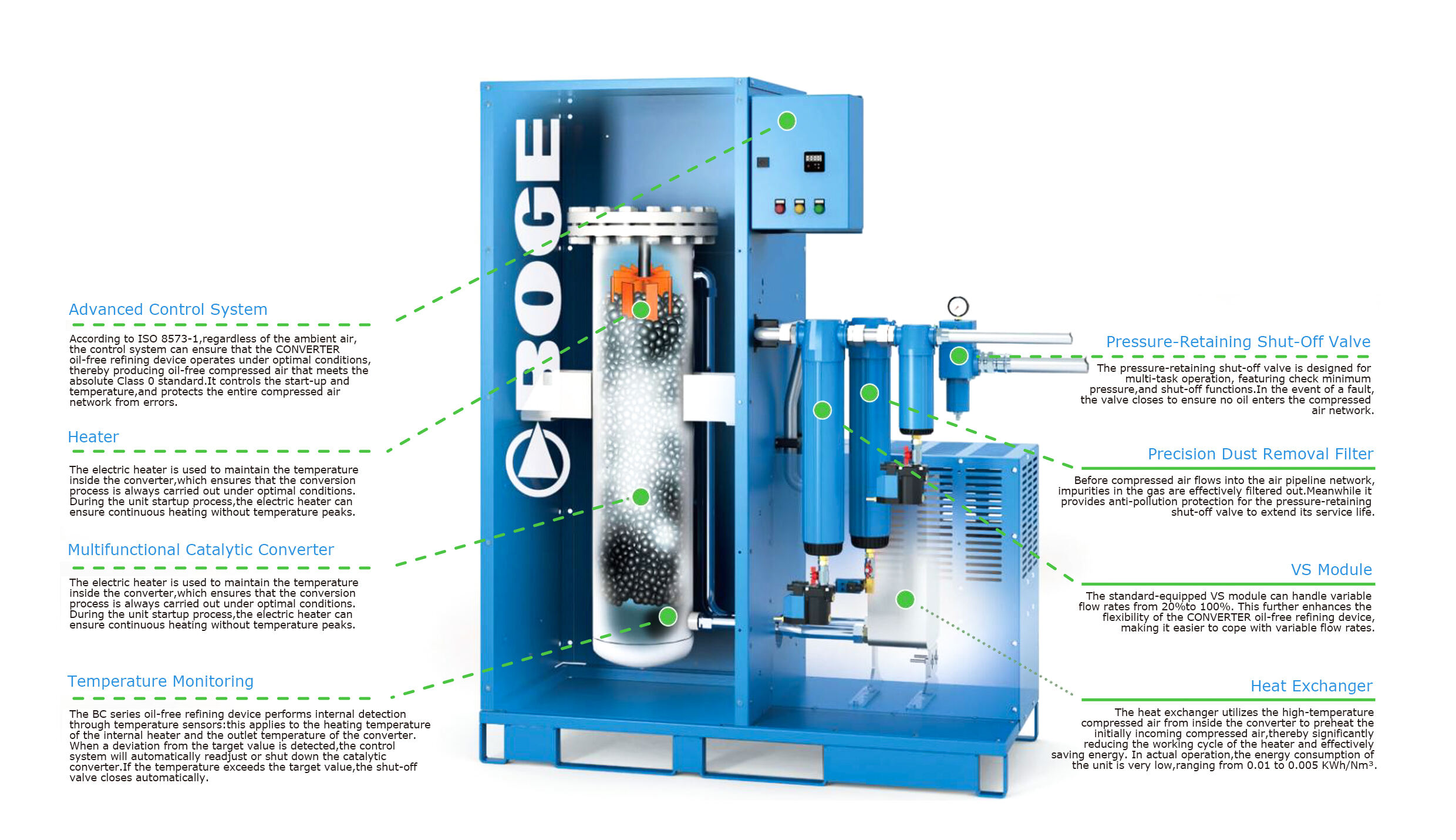

Product Introduction:

It is an oil-water barrier device designed for high-power laser air cutting.Equipped with Germany BOGE's oil-free refining technology and refrigerated drying technology,it fundamentally solves the problem of"oil pollution".After long-term operation of the equipment, the oil content and impurity content in the gas can still maintain the initial level,and there will be no degradation of air quality caused by "oil film failure or aging of the oil-gas separator".

Product Features:

●Suitable for any environment:The device operates completely independently of environmental and suction conditions,so it can be used in harsh working conditions with high dust levels during laser cutting.

●Maximum safety:To prevent any potential oil transfer,the device is equipped with two temperature monitors.If the temperature falls below or exceeds the limit temperature,the shut-off valve closes,the catalytic converter shuts down,and it directly indicates that the upstream air compressor requires maintenance. ●Self-evident cost comparison:In laser cutting applications that require the highest -quality oil-free compressed air,oil-free refining devices are the most economical and cost-effective solutions.When comparing costs over five years,the TCO(Total Cost of Ownership)—which takes into account all investment,operation,and service costs—is unparalleled in this purity class.

●Energy and maintenance cost savings:Compared with the quality of the compressed air produced,the energy cost is surprisingly low.The same applies to maintenance costs:since oil-free refining devices have no rotating parts,only minimal maintenance work is required.

Application Scenarios:

It is particularly suitable for ultra-high-power laser cutting scene which requires stable and constant air supply as the assist gas.