Fine Cutting ECO Series

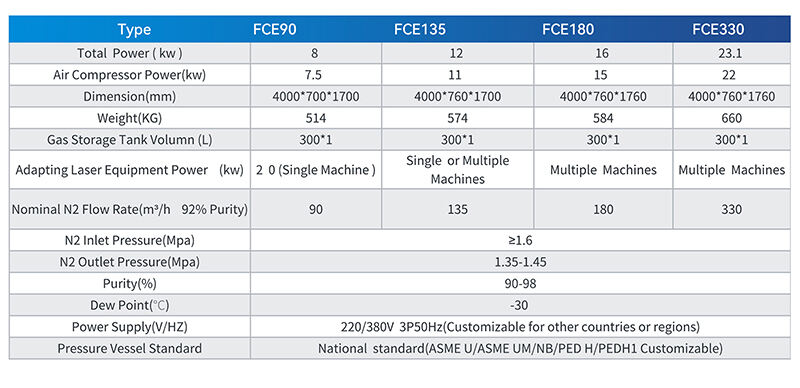

Product Type: FCE90/135/180/330

Cutting Material: Carbon steel plates/ galvanized plates/ high-quality aluminum alloy

Application

● Scenarios with high carbon steel cutting volume (replacing air cutting or liquid nitrogen cutting)

● Aluminum alloy burr-free cutting scenarios

Froduct Introduction

Fine Cutting ECO series is a gas mixing device designed for mixed gas cutting processes, used in scenarios where large-flow and fluctuating mixed gases serve as cutting gases in laser cutting. It consists of an air compressor, gas mixer, and premixing tank. Breaking through the traditional dual-path mixing method of nitrogen and oxygen, it adopts a single-path nitrogen with compressed air mixing mode to achieve lower operating costs.

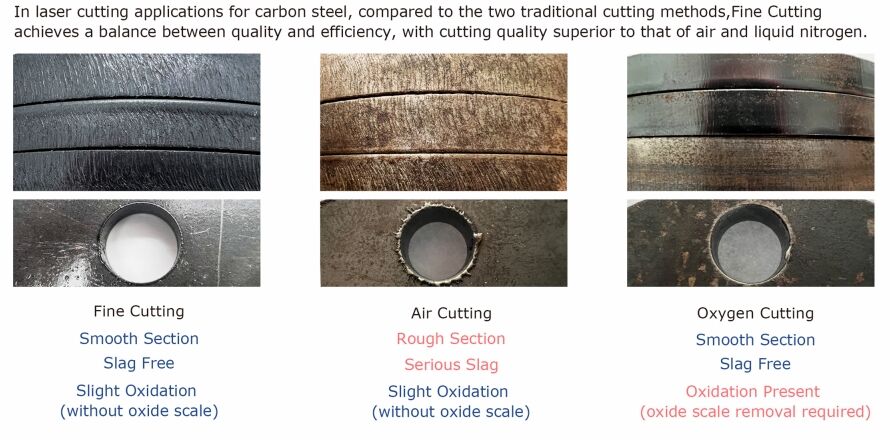

Advantages of Mixed Gas Cutting

● Improves cutting quality for ordinary steel, reducing burrs to <3% of material thickness;

● Higher surface finish compared to air cutting;

● Significantly increases cutting speed compared to high-power oxygen cutting for medium-thick carbon steel plates;

● More cost-effective compared to liquid nitrogen cutting.

Product Features

●Cost reduction of over 30% compared to dual-path gas mixing products;

●Electro-pneumatic proportional mixing valve provides infinitely variable mixing settings;

●Mobile APP terminal enables real-time monitoring or one-touch setting of working modes;

●Simple and intuitive operation; no certified personnel required;

●Unaffected by fluctuations in gas supply pressure.

Technical Specifications

Cutting Quality Comparison Fine Cutting VS Air and Oxygen