Kundnamn: HanXin Metal Material Plats: Shanghai, Kina Bransch: Bearbetning av metallplåtar och profiler Tillverkningsutrustning: Handhållen svetsmaskin 1,5 kW 1 enhet Skärarbete: Aluminiumlegeringsprofiler Gasspenslösning...

Dela

Kundnamn: HanXin metallmaterial

Plats: Shanghai, Kina

Industri: Bearbetning av plåt och profiler

Tillverkningsutrustning :Handhållen svetsmaskin 1,5 kW 1 enhet

Skärarbete :Aluminiumlegeringsprofiler

Gasförsösningslösning: Svetsmedel WMP03 (3 m 3/h 99,99 % kväveproduktion på plats) 1 enhet

Denna kund är en mindre anläggning för bearbetning av plåt och profiler som äger en laserskärare, en

handhållen svetsutrustning och en luftkompressor. Innan investeringen hyrde företagaren argongasflaskor som gasförsörjning till sin svetsmaskin. Efter jämförelse

valde han att investera i en egen gasgenerator. han hittade en svetsningsassistent som kostade honom bara lika mycket som en års hyra

kostnader. Och eftersom han redan har en luftkompressor är hela investeringen bara en enhet av svetsningsassistenten.

Genom att investera i denna lilla kvävegenerator förbättrade fabriken svetseffektiviteten avsevärt, förkortade

produktionscykler utan byte av flaskor.

Introduktion till Welding Mate-produkter:

Welding Mate är en kompakt kvävegenerator som säkerställer lokal produktion av kvävgas upp till 10 m³/h

(renhet 99,99 %). Denna allt-i-ett-kvävegenerator, baserad på PSA-teknik, är ett idealiskt val för små och

mellanstora företag som söker säker, ekonomisk, bekväm och tillförlitlig kväveförsörjning.

Ansökan

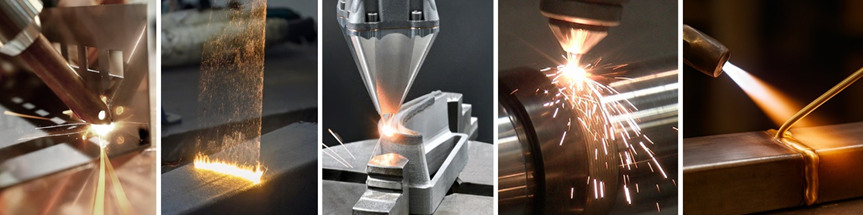

● Laser svetsning, rengöring, metall 3D-utskrift, värmebehandling, lödning, etc.

Produktspecifikationer:

● Lätt och flexibel för enkel integration: lämplig för handhållna laser svetsmaskiner

och kan enkelt integreras i svetsutrustning, oavsett om den är inbyggd eller externt monterad.

● Enkel drift med stabila och effektiva prestanda: Snabb igångsättning med renhet som snabbt uppfyller standardkrav,

intelligent start-stopp, automatisk avluftning och andra funktioner säkerställer en kontinuerlig, stabil och effektiv produktion av

99,99 % renhet, vilket möjliggör helt automatiserad drift.

● Säker, bekväm och låg kostnad: Jämfört med gasflaskor eller tankförsörjning, fungerar den vid lågt

tryck utan säkerhetsrisker, eliminerar behovet av produktionsavbrott för att byta gasflaskor, och

minskar användningskostnaderna till ungefär 10 % av cylindergas.